Product Description

B Series Short pitch Precision Triplex Roller Chains & Bush Chains

| ISO/DIN Chain No. |

Pitch

P |

Roller diameter

d1max |

Width between inner plates b1min mm |

Pin diameter

d2max |

Pin length | Inner plate depth h2max mm |

Plate thickness

t/Tmax |

Transverse pitch P mm |

Tensile strength

Qmin |

Average tensile strength Q0 kN |

Weight per meter q kg/m |

|

| Lmax mm |

Lcmax mm |

|||||||||||

| 64B-3 | 101.60 | 63.50 | 60.96 | 39.40 | 369.8 | 378.3 | 90.17 | 15.00/13.0 | 119.89 | 3000.0/681820 | 3300.0 | 136.00 |

*Straight side plates

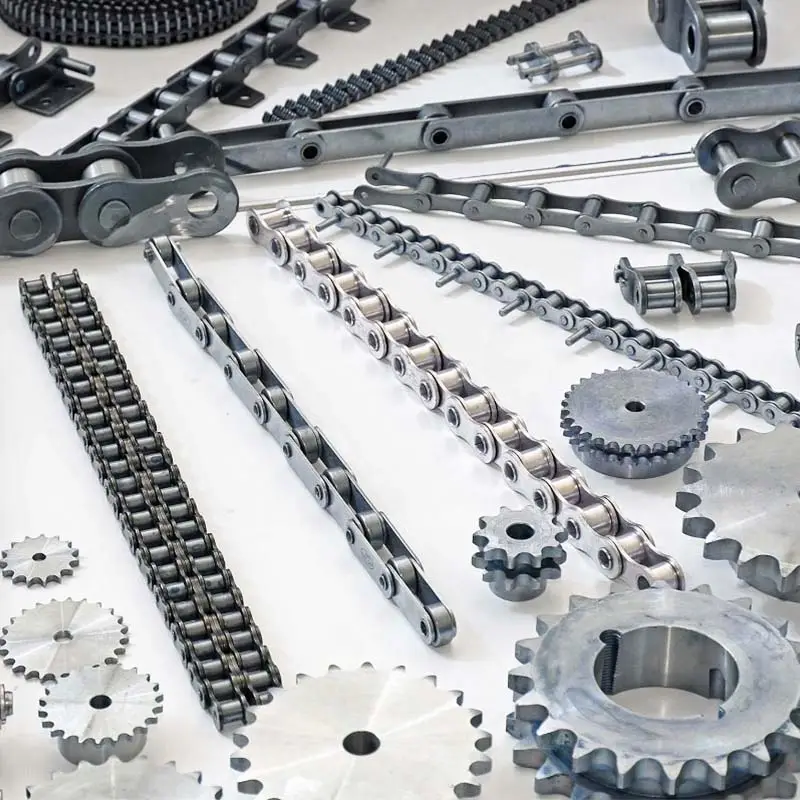

ROLLER CHAIN

Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic, industrial and agricultural machinery, including conveyors, wire- and tube-drawing machines, printing presses, cars, motorcycles, and bicycles. It consists of a series of short cylindrical rollers held together by side links. It is driven by a toothed wheel called a sprocket. It is a simple, reliable, and efficient means of power transmission.

CONSTRUCTION OF THE CHAIN

Two different sizes of roller chain, showing construction.

There are 2 types of links alternating in the bush roller chain. The first type is inner links, having 2 inner plates held together by 2 sleeves or bushings CHINAMFG which rotate 2 rollers. Inner links alternate with the second type, the outer links, consisting of 2 outer plates held together by pins passing through the bushings of the inner links. The “bushingless” roller chain is similar in operation though not in construction; instead of separate bushings or sleeves holding the inner plates together, the plate has a tube stamped into it protruding from the hole which serves the same purpose. This has the advantage of removing 1 step in assembly of the chain.

The roller chain design reduces friction compared to simpler designs, resulting in higher efficiency and less wear. The original power transmission chain varieties lacked rollers and bushings, with both the inner and outer plates held by pins which directly contacted the sprocket teeth; however this configuration exhibited extremely rapid wear of both the sprocket teeth, and the plates where they pivoted on the pins. This problem was partially solved by the development of bushed chains, with the pins holding the outer plates passing through bushings or sleeves connecting the inner plates. This distributed the wear over a greater area; however the teeth of the sprockets still wore more rapidly than is desirable, from the sliding friction against the bushings. The addition of rollers surrounding the bushing sleeves of the chain and provided rolling contact with the teeth of the sprockets resulting in excellent resistance to wear of both sprockets and chain as well. There is even very low friction, as long as the chain is sufficiently lubricated. Continuous, clean, lubrication of roller chains is of primary importance for efficient operation as well as correct tensioning.

LUBRICATION

Many driving chains (for example, in factory equipment, or driving a camshaft inside an internal combustion engine) operate in clean environments, and thus the wearing surfaces (that is, the pins and bushings) are safe from precipitation and airborne grit, many even in a sealed environment such as an oil bath. Some roller chains are designed to have o-rings built into the space between the outside link plate and the inside roller link plates. Chain manufacturers began to include this feature in 1971 after the application was invented by Joseph Montano while working for Whitney Chain of Hartford, Connecticut. O-rings were included as a way to improve lubrication to the links of power transmission chains, a service that is vitally important to extending their working life. These rubber fixtures form a barrier that holds factory applied lubricating grease inside the pin and bushing wear areas. Further, the rubber o-rings prevent dirt and other contaminants from entering inside the chain linkages, where such particles would otherwise cause significant wear.[citation needed]

There are also many chains that have to operate in dirty conditions, and for size or operational reasons cannot be sealed. Examples include chains on farm equipment, bicycles, and chain saws. These chains will necessarily have relatively high rates of wear, particularly when the operators are prepared to accept more friction, less efficiency, more noise and more frequent replacement as they neglect lubrication and adjustment.

Many oil-based lubricants attract dirt and other particles, eventually forming an CHINAMFG paste that will compound wear on chains. This problem can be circumvented by use of a “dry” PTFE spray, which forms a solid film after application and repels both particles and moisture.

VARIANTS DESIGN

Layout of a roller chain: 1. Outer plate, 2. Inner plate, 3. Pin, 4. Bushing, 5. Roller

If the chain is not being used for a high wear application (for instance if it is just transmitting motion from a hand-operated lever to a control shaft on a machine, or a sliding door on an oven), then 1 of the simpler types of chain may still be used. Conversely, where extra strength but the smooth drive of a smaller pitch is required, the chain may be “siamesed”; instead of just 2 rows of plates on the outer sides of the chain, there may be 3 (“duplex”), 4 (“triplex”), or more rows of plates running parallel, with bushings and rollers between each adjacent pair, and the same number of rows of teeth running in parallel on the sprockets to match. Timing chains on automotive engines, for example, typically have multiple rows of plates called strands.

Roller chain is made in several sizes, the most common American National Standards Institute (ANSI) standards being 40, 50, 60, and 80. The first digit(s) indicate the pitch of the chain in eighths of an inch, with the last digit being 0 for standard chain, 1 for lightweight chain, and 5 for bushed chain with no rollers. Thus, a chain with half-inch pitch would be a #40 while a #160 sprocket would have teeth spaced 2 inches apart, etc. Metric pitches are expressed in sixteenths of an inch; thus a metric #8 chain (08B-1) would be equivalent to an ANSI #40. Most roller chain is made from plain carbon or alloy steel, but stainless steel is used in food processing machinery or other places where lubrication is a problem, and nylon or brass are occasionally seen for the same reason.

Roller chain is ordinarily hooked up using a master link (also known as a connecting link), which typically has 1 pin held by a horseshoe clip rather than friction fit, allowing it to be inserted or removed with simple tools. Chain with a removable link or pin is also known as cottered chain, which allows the length of the chain to be adjusted. Half links (also known as offsets) are available and are used to increase the length of the chain by a single roller. Riveted roller chain has the master link (also known as a connecting link) “riveted” or mashed on the ends. These pins are made to be durable and are not removable.

USE

An example of 2 ‘ghost’ sprockets tensioning a triplex roller chain system

Roller chains are used in low- to mid-speed drives at around 600 to 800 feet per minute; however, at higher speeds, around 2,000 to 3,000 feet per minute, V-belts are normally used due to wear and noise issues.

A bicycle chain is a form of roller chain. Bicycle chains may have a master link, or may require a chain tool for removal and installation. A similar but larger and thus stronger chain is used on most motorcycles although it is sometimes replaced by either a toothed belt or a shaft drive, which offer lower noise level and fewer maintenance requirements.

The great majority of automobile engines use roller chains to drive the camshaft(s). Very high performance engines often use gear drive, and starting in the early 1960s toothed belts were used by some manufacturers.

Chains are also used in forklifts using hydraulic rams as a pulley to raise and lower the carriage; however, these chains are not considered roller chains, but are classified as lift or leaf chains.

Chainsaw cutting chains superficially resemble roller chains but are more closely related to leaf chains. They are driven by projecting drive links which also serve to locate the chain CHINAMFG the bar.

Sea Harrier FA.2 ZA195 front (cold) vector thrust nozzle – the nozzle is rotated by a chain drive from an air motor

A perhaps unusual use of a pair of motorcycle chains is in the Harrier Jump Jet, where a chain drive from an air motor is used to rotate the movable engine nozzles, allowing them to be pointed downwards for hovering flight, or to the rear for normal CHINAMFG flight, a system known as Thrust vectoring.

WEAR

The effect of wear on a roller chain is to increase the pitch (spacing of the links), causing the chain to grow longer. Note that this is due to wear at the pivoting pins and bushes, not from actual stretching of the metal (as does happen to some flexible steel components such as the hand-brake cable of a motor vehicle).

With modern chains it is unusual for a chain (other than that of a bicycle) to wear until it breaks, since a worn chain leads to the rapid onset of wear on the teeth of the sprockets, with ultimate failure being the loss of all the teeth on the sprocket. The sprockets (in particular the smaller of the two) suffer a grinding motion that puts a characteristic hook shape into the driven face of the teeth. (This effect is made worse by a chain improperly tensioned, but is unavoidable no matter what care is taken). The worn teeth (and chain) no longer provides smooth transmission of power and this may become evident from the noise, the vibration or (in car engines using a timing chain) the variation in ignition timing seen with a timing light. Both sprockets and chain should be replaced in these cases, since a new chain on worn sprockets will not last long. However, in less severe cases it may be possible to save the larger of the 2 sprockets, since it is always the smaller 1 that suffers the most wear. Only in very light-weight applications such as a bicycle, or in extreme cases of improper tension, will the chain normally jump off the sprockets.

The lengthening due to wear of a chain is calculated by the following formula:

M = the length of a number of links measured

S = the number of links measured

P = Pitch

In industry, it is usual to monitor the movement of the chain tensioner (whether manual or automatic) or the exact length of a drive chain (one rule of thumb is to replace a roller chain which has elongated 3% on an adjustable drive or 1.5% on a fixed-center drive). A simpler method, particularly suitable for the cycle or motorcycle user, is to attempt to pull the chain away from the larger of the 2 sprockets, whilst ensuring the chain is taut. Any significant movement (e.g. making it possible to see through a gap) probably indicates a chain worn up to and beyond the limit. Sprocket damage will result if the problem is ignored. Sprocket wear cancels this effect, and may mask chain wear.

CHAIN STRENGTH

The most common measure of roller chain’s strength is tensile strength. Tensile strength represents how much load a chain can withstand under a one-time load before breaking. Just as important as tensile strength is a chain’s fatigue strength. The critical factors in a chain’s fatigue strength is the quality of steel used to manufacture the chain, the heat treatment of the chain components, the quality of the pitch hole fabrication of the linkplates, and the type of shot plus the intensity of shot peen coverage on the linkplates. Other factors can include the thickness of the linkplates and the design (contour) of the linkplates. The rule of thumb for roller chain operating on a continuous drive is for the chain load to not exceed a mere 1/6 or 1/9 of the chain’s tensile strength, depending on the type of master links used (press-fit vs. slip-fit)[citation needed]. Roller chains operating on a continuous drive beyond these thresholds can and typically do fail prematurely via linkplate fatigue failure.

The standard minimum ultimate strength of the ANSI 29.1 steel chain is 12,500 x (pitch, in inches)2. X-ring and O-Ring chains greatly decrease wear by means of internal lubricants, increasing chain life. The internal lubrication is inserted by means of a vacuum when riveting the chain together.

CHAIN STHangZhouRDS

Standards organizations (such as ANSI and ISO) maintain standards for design, dimensions, and interchangeability of transmission chains. For example, the following Table shows data from ANSI standard B29.1-2011 (Precision Power Transmission Roller Chains, Attachments, and Sprockets) developed by the American Society of Mechanical Engineers (ASME). See the references[8][9][10] for additional information.

ASME/ANSI B29.1-2011 Roller Chain Standard SizesSizePitchMaximum Roller DiameterMinimum Ultimate Tensile StrengthMeasuring Load25

| ASME/ANSI B29.1-2011 Roller Chain Standard Sizes | ||||

| Size | Pitch | Maximum Roller Diameter | Minimum Ultimate Tensile Strength | Measuring Load |

|---|---|---|---|---|

| 25 | 0.250 in (6.35 mm) | 0.130 in (3.30 mm) | 780 lb (350 kg) | 18 lb (8.2 kg) |

| 35 | 0.375 in (9.53 mm) | 0.200 in (5.08 mm) | 1,760 lb (800 kg) | 18 lb (8.2 kg) |

| 41 | 0.500 in (12.70 mm) | 0.306 in (7.77 mm) | 1,500 lb (680 kg) | 18 lb (8.2 kg) |

| 40 | 0.500 in (12.70 mm) | 0.312 in (7.92 mm) | 3,125 lb (1,417 kg) | 31 lb (14 kg) |

| 50 | 0.625 in (15.88 mm) | 0.400 in (10.16 mm) | 4,880 lb (2,210 kg) | 49 lb (22 kg) |

| 60 | 0.750 in (19.05 mm) | 0.469 in (11.91 mm) | 7,030 lb (3,190 kg) | 70 lb (32 kg) |

| 80 | 1.000 in (25.40 mm) | 0.625 in (15.88 mm) | 12,500 lb (5,700 kg) | 125 lb (57 kg) |

| 100 | 1.250 in (31.75 mm) | 0.750 in (19.05 mm) | 19,531 lb (8,859 kg) | 195 lb (88 kg) |

| 120 | 1.500 in (38.10 mm) | 0.875 in (22.23 mm) | 28,125 lb (12,757 kg) | 281 lb (127 kg) |

| 140 | 1.750 in (44.45 mm) | 1.000 in (25.40 mm) | 38,280 lb (17,360 kg) | 383 lb (174 kg) |

| 160 | 2.000 in (50.80 mm) | 1.125 in (28.58 mm) | 50,000 lb (23,000 kg) | 500 lb (230 kg) |

| 180 | 2.250 in (57.15 mm) | 1.460 in (37.08 mm) | 63,280 lb (28,700 kg) | 633 lb (287 kg) |

| 200 | 2.500 in (63.50 mm) | 1.562 in (39.67 mm) | 78,175 lb (35,460 kg) | 781 lb (354 kg) |

| 240 | 3.000 in (76.20 mm) | 1.875 in (47.63 mm) | 112,500 lb (51,000 kg) | 1,000 lb (450 kg |

For mnemonic purposes, below is another presentation of key dimensions from the same standard, expressed in fractions of an inch (which was part of the thinking behind the choice of preferred numbers in the ANSI standard):

| Pitch (inches) | Pitch expressed in eighths |

ANSI standard chain number |

Width (inches) |

|---|---|---|---|

| 1⁄4 | 2⁄8 | 25 | 1⁄8 |

| 3⁄8 | 3⁄8 | 35 | 3⁄16 |

| 1⁄2 | 4⁄8 | 41 | 1⁄4 |

| 1⁄2 | 4⁄8 | 40 | 5⁄16 |

| 5⁄8 | 5⁄8 | 50 | 3⁄8 |

| 3⁄4 | 6⁄8 | 60 | 1⁄2 |

| 1 | 8⁄8 | 80 | 5⁄8 |

Notes:

1. The pitch is the distance between roller centers. The width is the distance between the link plates (i.e. slightly more than the roller width to allow for clearance).

2. The right-hand digit of the standard denotes 0 = normal chain, 1 = lightweight chain, 5 = rollerless bushing chain.

3. The left-hand digit denotes the number of eighths of an inch that make up the pitch.

4. An “H” following the standard number denotes heavyweight chain. A hyphenated number following the standard number denotes double-strand (2), triple-strand (3), and so on. Thus 60H-3 denotes number 60 heavyweight triple-strand chain.

A typical bicycle chain (for derailleur gears) uses narrow 1⁄2-inch-pitch chain. The width of the chain is variable, and does not affect the load capacity. The more sprockets at the rear wheel (historically 3-6, nowadays 7-12 sprockets), the narrower the chain. Chains are sold according to the number of speeds they are designed to work with, for example, “10 speed chain”. Hub gear or single speed bicycles use 1/2″ x 1/8″ chains, where 1/8″ refers to the maximum thickness of a sprocket that can be used with the chain.

Typically chains with parallel shaped links have an even number of links, with each narrow link followed by a broad one. Chains built up with a uniform type of link, narrow at 1 and broad at the other end, can be made with an odd number of links, which can be an advantage to adapt to a special chainwheel-distance; on the other side such a chain tends to be not so strong.

Roller chains made using ISO standard are sometimes called as isochains.

WHY CHOOSE US

1. Reliable Quality Assurance System

2. Cutting-Edge Computer-Controlled CNC Machines

3. Bespoke Solutions from Highly Experienced Specialists

4. Customization and OEM Available for Specific Application

5. Extensive Inventory of Spare Parts and Accessories

6. Well-Developed CHINAMFG Marketing Network

7. Efficient After-Sale Service System

The 219 sets of advanced automatic production equipment provide guarantees for high product quality. The 167 engineers and technicians with senior professional titles can design and develop products to meet the exact demands of customers, and OEM customizations are also available with us. Our sound global service network can provide customers with timely after-sales technical services.

We are not just a manufacturer and supplier, but also an industry consultant. We work pro-actively with you to offer expert advice and product recommendations in order to end up with a most cost effective product available for your specific application. The clients we serve CHINAMFG range from end users to distributors and OEMs. Our OEM replacements can be substituted wherever necessary and suitable for both repair and new assemblies.

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery, Car, Food and Beverage Industry, Motorcycle Parts |

| Surface Treatment: | Polishing |

| Samples: |

US$ 0/Meter

1 Meter(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the noise and vibration characteristics of engineering chains?

Engineering chains, like other types of roller chains, can produce noise and vibrations during their operation. The noise and vibration characteristics of engineering chains depend on several factors:

- Lubrication: Proper lubrication of the chain can help reduce friction between the chain’s components, leading to smoother operation and lower noise levels.

- Chain Condition: A well-maintained chain with proper tension and minimal wear is likely to produce less noise and vibration compared to a worn or damaged chain.

- Alignment: Proper alignment of the sprockets and the chain is essential to minimize lateral forces, which can contribute to increased noise and vibration.

- Load and Speed: Heavier loads and higher speeds can increase the dynamic forces within the chain, leading to more pronounced noise and vibration.

- Environmental Factors: External factors, such as temperature, humidity, and contaminants, can influence the chain’s noise and vibration characteristics.

Chain noise and vibration can be managed through various measures:

- Chain Design: Some chains are designed with noise reduction features, such as special profile plates or noise-dampening materials.

- Lubrication: Using high-quality and appropriate lubricants can help reduce friction and noise.

- Tensioning: Properly tensioned chains experience less vibration and are less likely to produce noise.

- Maintenance: Regular inspection and maintenance can identify and address any issues that may contribute to increased noise and vibration.

- Isolation: In some applications, adding vibration isolators or dampeners can help reduce the transmission of noise and vibrations to surrounding structures.

It’s important to consider the specific requirements of the application and consult with chain manufacturers or experts to select the most suitable engineering chain and implement noise and vibration mitigation strategies when necessary.

What are the benefits of using an engineering chain over other power transmission methods?

Engineering chains offer several advantages over other power transmission methods, making them a preferred choice in various industrial applications:

- High Strength: Engineering chains are designed to handle heavy loads and high torque, making them suitable for demanding applications that require robust and reliable power transmission.

- Wide Range of Sizes: These chains are available in a wide range of sizes and configurations, allowing for flexibility in design and accommodating various application requirements.

- Durable and Long-Lasting: When properly maintained, engineering chains have a long service life, reducing the need for frequent replacements and minimizing downtime in industrial operations.

- Adaptable to Harsh Environments: Engineering chains are capable of operating in harsh conditions, including dusty, dirty, or corrosive environments, without compromising their performance.

- Shock Load Resistance: The design of engineering chains allows them to handle sudden impact forces and shock loads, which can occur in certain industrial processes.

- Cost-Effective: Engineering chains often provide a cost-effective solution for power transmission compared to other methods, especially in high-load applications.

- Simple Installation: With proper alignment and tensioning, engineering chains are relatively easy to install, reducing installation time and labor costs.

- Bi-Directional Power Transmission: Engineering chains can transmit power in both forward and reverse directions, making them suitable for applications requiring bidirectional motion.

- Low Maintenance: Regular maintenance, such as lubrication and inspection, can keep engineering chains in good working condition, reducing overall maintenance costs.

- Reduction of Noise and Vibration: When adequately lubricated and aligned, engineering chains can operate quietly and with minimal vibration, contributing to a more comfortable and safer working environment.

Despite their many advantages, it’s essential to consider the specific requirements of each application before selecting an engineering chain. Factors such as load capacity, speed, environmental conditions, and space constraints should be taken into account to ensure the chain’s optimal performance and longevity.

In summary, engineering chains are a versatile and reliable power transmission method, offering a range of benefits that make them well-suited for use in various industrial settings.

What materials are engineering chains typically made of?

Engineering chains are commonly made from a variety of durable and high-strength materials to ensure their performance and longevity in demanding industrial applications. The choice of material depends on factors such as the application’s requirements, environmental conditions, and the specific type of engineering chain. Some of the typical materials used for engineering chains include:

1. Carbon Steel: Carbon steel is a popular choice for engineering chains due to its excellent strength and affordability. It is suitable for many standard industrial applications where moderate strength and resistance to wear are required.

2. Alloy Steel: Alloy steel offers higher strength and better resistance to wear and fatigue compared to carbon steel. It is commonly used in heavy-duty and high-stress applications, such as mining equipment and construction machinery.

3. Stainless Steel: Stainless steel is chosen for its corrosion resistance properties, making it ideal for applications where the chain may be exposed to moisture, chemicals, or harsh environments. It is commonly used in food processing, pharmaceuticals, and outdoor applications.

4. Nickel-Plated Steel: Nickel-plated steel chains provide enhanced corrosion resistance while retaining the strength of carbon or alloy steel. They are often used in applications where both strength and corrosion resistance are important.

5. Plastic: In some cases, engineering chains may be constructed entirely from plastic or have plastic components. Plastic chains are commonly used in industries requiring low noise, lightweight, and corrosion resistance, such as the food and beverage industry and packaging applications.

6. Other Specialty Materials: Depending on the specific requirements of an application, engineering chains may also be made from other specialty materials like bronze, zinc-plated steel, or coated chains to meet particular needs.

The choice of material is crucial in determining the performance, longevity, and suitability of the engineering chain for a specific application. Manufacturers provide information on the material composition of their chains, allowing users to select the most appropriate material based on the intended use and operating conditions.

editor by CX 2023-11-20

China OEM Manufacturer 10ass Simplex Stainless Steel Gearbox Belt Transmission Parts Engineering and Construction Machinery Short Pitch Roller Chains and Bush Chain

Product Description

| Chain No. | Pitch

P |

Roller diameter

d1max |

Width between inner plates b1min mm |

Pin diameter

d2max |

Pin length | Inner plate depth h2max mm |

Plate thickness t/Tmax mm |

Transverse pitch Pt mm |

Breaking load

Q |

Weight per meter q kg/m |

|

| Lmax mm |

Lcmax mm |

||||||||||

| 12BSS-3 | 19.050 | 12.07 | 11.68 | 5.72 | 61.50 | 63.10 | 16.00 | 1.85 | 19.46 | 55.5/12477 | 3.71 |

*Bush chain:d1 in the table indicates the external diameter of the bush

*Straight side plates

Stainless steel chains are suitable for corrosive conditions involving food,chemicals pharmaceuticals,etc.and also suitable for high and low temperature conditions.

productList?selectedSpotlightId=lQfxnMwuuTRv

Products Image

Roller chain

Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic, industrial and agricultural machinery, including conveyors, wire- and tube-drawing machines, printing presses, cars, motorcycles, and bicycles. It consists of a series of short cylindrical rollers held together by side links. It is driven by a toothed wheel called a sprocket. It is a simple, reliable, and efficient[1] means of power transmission.

Though CHINAMFG Renold is credited with inventing the roller chain in 1880, sketches by Leonardo da Vinci in the 16th century show a chain with a roller bearing.

Construction of the chain

Two different sizes of roller chain, showing construction.

There are 2 types of links alternating in the bush roller chain. The first type is inner links, having 2 inner plates held together by 2 sleeves or bushings CHINAMFG which rotate 2 rollers. Inner links alternate with the second type, the outer links, consisting of 2 outer plates held together by pins passing through the bushings of the inner links. The “bushingless” roller chain is similar in operation though not in construction; instead of separate bushings or sleeves holding the inner plates together, the plate has a tube stamped into it protruding from the hole which serves the same purpose. This has the advantage of removing 1 step in assembly of the chain.

The roller chain design reduces friction compared to simpler designs, resulting in higher efficiency and less wear. The original power transmission chain varieties lacked rollers and bushings, with both the inner and outer plates held by pins which directly contacted the sprocket teeth; however this configuration exhibited extremely rapid wear of both the sprocket teeth, and the plates where they pivoted on the pins. This problem was partially solved by the development of bushed chains, with the pins holding the outer plates passing through bushings or sleeves connecting the inner plates. This distributed the wear over a greater area; however the teeth of the sprockets still wore more rapidly than is desirable, from the sliding friction against the bushings. The addition of rollers surrounding the bushing sleeves of the chain and provided rolling contact with the teeth of the sprockets resulting in excellent resistance to wear of both sprockets and chain as well. There is even very low friction, as long as the chain is sufficiently lubricated. Continuous, clean, lubrication of roller chains is of primary importance for efficient operation as well as correct tensioning.

Lubrication

Many driving chains (for example, in factory equipment, or driving a camshaft inside an internal combustion engine) operate in clean environments, and thus the wearing surfaces (that is, the pins and bushings) are safe from precipitation and airborne grit, many even in a sealed environment such as an oil bath. Some roller chains are designed to have o-rings built into the space between the outside link plate and the inside roller link plates. Chain manufacturers began to include this feature in 1971 after the application was invented by Joseph Montano while working for Whitney Chain of Hartford, Connecticut. O-rings were included as a way to improve lubrication to the links of power transmission chains, a service that is vitally important to extending their working life. These rubber fixtures form a barrier that holds factory applied lubricating grease inside the pin and bushing wear areas. Further, the rubber o-rings prevent dirt and other contaminants from entering inside the chain linkages, where such particles would otherwise cause significant wear.[citation needed]

There are also many chains that have to operate in dirty conditions, and for size or operational reasons cannot be sealed. Examples include chains on farm equipment, bicycles, and chain saws. These chains will necessarily have relatively high rates of wear, particularly when the operators are prepared to accept more friction, less efficiency, more noise and more frequent replacement as they neglect lubrication and adjustment.

Many oil-based lubricants attract dirt and other particles, eventually forming an CHINAMFG paste that will compound wear on chains. This problem can be circumvented by use of a “dry” PTFE spray, which forms a solid film after application and repels both particles and moisture.

Variants in design

Layout of a roller chain: 1. Outer plate, 2. Inner plate, 3. Pin, 4. Bushing, 5. Roller

If the chain is not being used for a high wear application (for instance if it is just transmitting motion from a hand-operated lever to a control shaft on a machine, or a sliding door on an oven), then 1 of the simpler types of chain may still be used. Conversely, where extra strength but the smooth drive of a smaller pitch is required, the chain may be “siamesed”; instead of just 2 rows of plates on the outer sides of the chain, there may be 3 (“duplex”), 4 (“triplex”), or more rows of plates running parallel, with bushings and rollers between each adjacent pair, and the same number of rows of teeth running in parallel on the sprockets to match. Timing chains on automotive engines, for example, typically have multiple rows of plates called strands.

Roller chain is made in several sizes, the most common American National Standards Institute (ANSI) standards being 40, 50, 60, and 80. The first digit(s) indicate the pitch of the chain in eighths of an inch, with the last digit being 0 for standard chain, 1 for lightweight chain, and 5 for bushed chain with no rollers. Thus, a chain with half-inch pitch would be a #40 while a #160 sprocket would have teeth spaced 2 inches apart, etc. Metric pitches are expressed in sixteenths of an inch; thus a metric #8 chain (08B-1) would be equivalent to an ANSI #40. Most roller chain is made from plain carbon or alloy steel, but stainless steel is used in food processing machinery or other places where lubrication is a problem, and nylon or brass are occasionally seen for the same reason.

Roller chain is ordinarily hooked up using a master link (also known as a connecting link), which typically has 1 pin held by a horseshoe clip rather than friction fit, allowing it to be inserted or removed with simple tools. Chain with a removable link or pin is also known as cottered chain, which allows the length of the chain to be adjusted. Half links (also known as offsets) are available and are used to increase the length of the chain by a single roller. Riveted roller chain has the master link (also known as a connecting link) “riveted” or mashed on the ends. These pins are made to be durable and are not removable.

Use

An example of 2 ‘ghost’ sprockets tensioning a triplex roller chain system

Roller chains are used in low- to mid-speed drives at around 600 to 800 feet per minute; however, at higher speeds, around 2,000 to 3,000 feet per minute, V-belts are normally used due to wear and noise issues.

A bicycle chain is a form of roller chain. Bicycle chains may have a master link, or may require a chain tool for removal and installation. A similar but larger and thus stronger chain is used on most motorcycles although it is sometimes replaced by either a toothed belt or a shaft drive, which offer lower noise level and fewer maintenance requirements.

The great majority of automobile engines use roller chains to drive the camshaft(s). Very high performance engines often use gear drive, and starting in the early 1960s toothed belts were used by some manufacturers.

Chains are also used in forklifts using hydraulic rams as a pulley to raise and lower the carriage; however, these chains are not considered roller chains, but are classified as lift or leaf chains.

Chainsaw cutting chains superficially resemble roller chains but are more closely related to leaf chains. They are driven by projecting drive links which also serve to locate the chain CHINAMFG the bar.

Sea Harrier FA.2 ZA195 front (cold) vector thrust nozzle – the nozzle is rotated by a chain drive from an air motor

A perhaps unusual use of a pair of motorcycle chains is in the Harrier Jump Jet, where a chain drive from an air motor is used to rotate the movable engine nozzles, allowing them to be pointed downwards for hovering flight, or to the rear for normal CHINAMFG flight, a system known as Thrust vectoring.

Wear

The effect of wear on a roller chain is to increase the pitch (spacing of the links), causing the chain to grow longer. Note that this is due to wear at the pivoting pins and bushes, not from actual stretching of the metal (as does happen to some flexible steel components such as the hand-brake cable of a motor vehicle).

With modern chains it is unusual for a chain (other than that of a bicycle) to wear until it breaks, since a worn chain leads to the rapid onset of wear on the teeth of the sprockets, with ultimate failure being the loss of all the teeth on the sprocket. The sprockets (in particular the smaller of the two) suffer a grinding motion that puts a characteristic hook shape into the driven face of the teeth. (This effect is made worse by a chain improperly tensioned, but is unavoidable no matter what care is taken). The worn teeth (and chain) no longer provides smooth transmission of power and this may become evident from the noise, the vibration or (in car engines using a timing chain) the variation in ignition timing seen with a timing light. Both sprockets and chain should be replaced in these cases, since a new chain on worn sprockets will not last long. However, in less severe cases it may be possible to save the larger of the 2 sprockets, since it is always the smaller 1 that suffers the most wear. Only in very light-weight applications such as a bicycle, or in extreme cases of improper tension, will the chain normally jump off the sprockets.

The lengthening due to wear of a chain is calculated by the following formula:

{\displaystyle \%=((M-(S*P))/(S*P))*100}

M = the length of a number of links measured

S = the number of links measured

P = Pitch

In industry, it is usual to monitor the movement of the chain tensioner (whether manual or automatic) or the exact length of a drive chain (one rule of thumb is to replace a roller chain which has elongated 3% on an adjustable drive or 1.5% on a fixed-center drive). A simpler method, particularly suitable for the cycle or motorcycle user, is to attempt to pull the chain away from the larger of the 2 sprockets, whilst ensuring the chain is taut. Any significant movement (e.g. making it possible to see through a gap) probably indicates a chain worn up to and beyond the limit. Sprocket damage will result if the problem is ignored. Sprocket wear cancels this effect, and may mask chain wear.

Chain strength

The most common measure of roller chain’s strength is tensile strength. Tensile strength represents how much load a chain can withstand under a one-time load before breaking. Just as important as tensile strength is a chain’s fatigue strength. The critical factors in a chain’s fatigue strength is the quality of steel used to manufacture the chain, the heat treatment of the chain components, the quality of the pitch hole fabrication of the linkplates, and the type of shot plus the intensity of shot peen coverage on the linkplates. Other factors can include the thickness of the linkplates and the design (contour) of the linkplates. The rule of thumb for roller chain operating on a continuous drive is for the chain load to not exceed a mere 1/6 or 1/9 of the chain’s tensile strength, depending on the type of master links used (press-fit vs. slip-fit)[citation needed]. Roller chains operating on a continuous drive beyond these thresholds can and typically do fail prematurely via linkplate fatigue failure.

The standard minimum ultimate strength of the ANSI 29.1 steel chain is 12,500 x (pitch, in inches)2. X-ring and O-Ring chains greatly decrease wear by means of internal lubricants, increasing chain life. The internal lubrication is inserted by means of a vacuum when riveting the chain together.

Chain standards

Standards organizations (such as ANSI and ISO) maintain standards for design, dimensions, and interchangeability of transmission chains. For example, the following Table shows data from ANSI standard B29.1-2011 (Precision Power Transmission Roller Chains, Attachments, and Sprockets) developed by the American Society of Mechanical Engineers (ASME). See the references[8][9][10] for additional information.

ASME/ANSI B29.1-2011 Roller Chain Standard SizesSizePitchMaximum Roller DiameterMinimum Ultimate Tensile StrengthMeasuring Load25.

For mnemonic purposes, below is another presentation of key dimensions from the same standard, expressed in fractions of an inch (which was part of the thinking behind the choice of preferred numbers in the ANSI standard):

Notes:

1. The pitch is the distance between roller centers. The width is the distance between the link plates (i.e. slightly more than the roller width to allow for clearance).

2. The right-hand digit of the standard denotes 0 = normal chain, 1 = lightweight chain, 5 = rollerless bushing chain.

3. The left-hand digit denotes the number of eighths of an inch that make up the pitch.

4. An “H” following the standard number denotes heavyweight chain. A hyphenated number following the standard number denotes double-strand (2), triple-strand (3), and so on. Thus 60H-3 denotes number 60 heavyweight triple-strand chain.

A typical bicycle chain (for derailleur gears) uses narrow 1⁄2-inch-pitch chain. The width of the chain is variable, and does not affect the load capacity. The more sprockets at the rear wheel (historically 3-6, nowadays 7-12 sprockets), the narrower the chain. Chains are sold according to the number of speeds they are designed to work with, for example, “10 speed chain”. Hub gear or single speed bicycles use 1/2″ x 1/8″ chains, where 1/8″ refers to the maximum thickness of a sprocket that can be used with the chain.

Typically chains with parallel shaped links have an even number of links, with each narrow link followed by a broad one. Chains built up with a uniform type of link, narrow at 1 and broad at the other end, can be made with an odd number of links, which can be an advantage to adapt to a special chainwheel-distance; on the other side such a chain tends to be not so strong.

Roller chains made using ISO standard are sometimes called as isochains.

More Products

Company Workshop

Company Certificates

Package for reference

Q:Why choose us ?

A. we are a manufacturer, we have manufactured valve for over 20 years .

B. Reliable Quality Assurance System;

C. Cutting-Edge Computer-Controlled CNC Machines;

D. Bespoke Solutions from Highly Experienced Specialists;

E. Customization and OEM Available for Specific Application;

F. Extensive Inventory of Spare Parts and Accessories;

G. Well-Developed CHINAMFG Marketing Network;

H. Efficient After-Sale Service System

Q. what is your payment term?

A: 30% TT deposit, 70% balance T/T before shipping.

Q:Can we print our logo on your products?

A: yes, we offer OEM/ODM service, we support the customized logo, size, package,etc.

Q: Can you make chains according to my CAD drawings?

A: Yes. Besides the regular standard chains, we produce non-standard and custom-design products to meet the specific technical requirements. In reality, a sizable portion of our production capacity is assigned to make non-standard products.

Q: what is your main market?

A: North America, South America, Eastern Europe, Western Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia,

Q: Can I get samples from your factory?

A: Yes, Samples can be provided.

| Standard or Nonstandard: | Standard, Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Electric Cars, Motorcycle, Food Machinery, Agricultural Machinery, Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery, Car, Food and Beverage Industry, Motorcycle Parts |

| Surface Treatment: | Polishing, Polishing |

| Structure: | Roller Chain, Rotransmission Chain, Pulling Chain, Driving Chain |

| Material: | Stainless Steel, Rubber |

| Type: | Bush Chain, Transmission Chain, Pulling Chain, Driving Chain |

| Samples: |

US$ 0/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do engineering chains handle misalignment between sprockets?

Engineering chains are designed to handle some degree of misalignment between sprockets. Misalignment can occur due to various factors such as improper installation, wear and elongation of the chain, or inaccuracies in the machinery. While some misalignment is inevitable in many industrial applications, excessive misalignment should be avoided to ensure optimal chain performance and longevity.

Here’s how engineering chains handle misalignment:

- Flexible Construction: Engineering chains are constructed with flexible components such as pins, rollers, and bushings. This design allows the chain to adapt to minor misalignments without putting excessive stress on the chain or sprockets.

- Articulating Joints: The articulating joints in the chain allow it to articulate smoothly around the sprockets, accommodating minor misalignment during the rotation. This helps reduce wear on the chain and sprockets.

- Tolerance for Misalignment: Manufacturers provide specifications for the allowable misalignment between sprockets. Engineering chains are designed to handle a certain level of misalignment within these tolerances without significantly affecting their performance.

- Proper Installation: Correct installation of the engineering chain is crucial to minimizing misalignment issues. Ensuring proper tension, alignment, and center-to-center distance between sprockets can help reduce misalignment and prolong chain life.

- Regular Maintenance: Regular maintenance, including chain inspection and lubrication, can help identify and address misalignment issues early on. Promptly correcting misalignment can prevent further damage and ensure efficient chain operation.

- Alignment Devices: In some cases, alignment devices or tools may be used during installation to ensure accurate alignment between the sprockets. These devices can help improve chain performance and reduce wear caused by misalignment.

It is essential to follow the manufacturer’s guidelines for chain installation, maintenance, and alignment to optimize the performance and service life of engineering chains. Addressing misalignment issues promptly and keeping the chain in proper working condition will contribute to the overall reliability and efficiency of the machinery or equipment in which the chain is used.

Can engineering chains be used for power transmission in conveyor systems?

Yes, engineering chains are commonly used for power transmission in conveyor systems. Conveyor systems are widely employed in various industries for material handling, and they require reliable and efficient power transmission methods to move heavy loads over long distances. Engineering chains are well-suited for these applications due to their robust construction, high load-carrying capacity, and versatility.

Conveyor systems often consist of a series of sprockets and a continuous loop of engineering chain that runs over these sprockets. The chain is driven by a motorized sprocket, and as it moves, it carries the conveyed material along the conveyor’s length. The design of engineering chains ensures smooth engagement with the sprockets, enabling efficient power transmission and precise material handling.

Depending on the specific requirements of the conveyor system, various types of engineering chains can be used. For instance, for applications where cleanliness is crucial, stainless steel chains with self-lubricating properties may be employed. In environments with high corrosion potential, corrosion-resistant coatings on chain components can extend the chain’s lifespan.

Furthermore, engineering chains can be customized to fit different conveyor configurations, allowing for the design of complex conveyor systems that suit specific production processes or spatial limitations.

In summary, engineering chains are an excellent choice for power transmission in conveyor systems due to their durability, load capacity, and adaptability. They ensure smooth and reliable operation, making them indispensable in material handling and conveyor applications across various industries.

Can engineering chains be used in corrosive or harsh environments?

Yes, engineering chains can be designed and manufactured to withstand corrosive or harsh environments. When operating in such conditions, it is crucial to select the appropriate materials and coatings for the chain to ensure its durability and performance. Here are some considerations for using engineering chains in corrosive or harsh environments:

1. Material Selection: Choose materials that have high corrosion resistance, such as stainless steel or nickel-plated chains. These materials can withstand exposure to moisture, chemicals, and other corrosive agents.

2. Coatings and Surface Treatments: Applying specialized coatings or surface treatments to the chain can further enhance its corrosion resistance. Common coatings include zinc plating, chromate conversion coating, and polymer coatings.

3. Sealed Joints: Opt for engineering chains with sealed joints or special seals to protect the internal components from contaminants and moisture, reducing the risk of corrosion.

4. Environmental Ratings: Some engineering chains may come with specific environmental ratings that indicate their suitability for certain conditions. Check these ratings to ensure the chain is appropriate for the intended environment.

5. Regular Maintenance: Even with corrosion-resistant materials and coatings, regular maintenance is essential. Keep the chain clean, lubricated, and free from debris to prevent corrosion and premature wear.

6. Compatibility with Other Components: Ensure that all components in the chain system, such as sprockets and bearings, are also suitable for use in corrosive environments.

7. Temperature Considerations: Take into account the operating temperature range of the environment. Some materials may perform differently at extreme temperatures, affecting the chain’s overall performance.

8. Chemical Exposure: If the chain will be exposed to specific chemicals or substances, verify that the chosen materials and coatings are resistant to those chemicals.

By carefully selecting the right materials, coatings, and design features, engineering chains can effectively handle corrosive or harsh environments, maintaining their functionality and longevity in challenging industrial applications.

editor by CX 2023-10-26

China Custom EP-RC51 Agricultural Lawn Mower Gearbox near me factory

EP-RC51 Agricultural Lawn Mower Gearbox

| ITEM | EP-RC51 Lawn Mower Gearbox |

| Ratio | 1:1.47/1:1.93 |

| Teeth | 22/15 29/15 |

| Module | 5.08 /4.0 |

| Power(HP) | 30 |

| Rated Input | 540rpm |

| Input/Output Description | Spline /Taper spline |

| Weight(N.W) | 29KG |

We supply different power Agricultural gearboxes, also we could offer OEM/ ODM service according to your drawing / sample.RG series have the features of high versatility,good combination and heavy loading capability, along with other merits such as easy to attain various transmission ratios, high efficiency.We supply different power Agricultural gearboxes, also we could offer OEM/ ODM service according to your drawing / sample.

1.We have 20 years ODM &OEM experience for gearbox

2.Goods 100% be tested before shippment

3.24 Hours for services

4.ODM & OEM: The technology Dpt. Can R&D new mould according to customer’s requirement.

5.The favorable factory price

6.Package and Brand can be Customized

Lawn Mower Gearbox Lubrication Instructions:

NOTE: These instructions apply to all Mower decks with gear-driven blades. For the mower with belt-driven blades, see Mower Deck Lubrication in this section.

Lawn Mower Gearbox (Tee Gearbox and Blade drive gearbox) connected as an integral component, Oil flows freely between them.

This type of agricultural gearbox is permanently lubricated (oil-filled) and sealed and does not require periodic lubrication.

However, the transmission oil seal should be checked every 25 hours for signs of oil spills; In particular, the lower seal of the blade drive gearbox should be checked, Because they operate in a dirty environment.

If oil leaks are found, replace the oil seals and relubricate the gearbox assembly as follows:

1. Remove the Lawn Mower Gearbox cover (foot pedal). deck direction Should be in the normal operating position.

2. Clean the area around a single Lawn Mower Gearbox Cover to prevent contamination from entering Gearbox.

3. Remove the fixing Screws for blade drive gearbox cover.

4. Check the lubricant level in the gearbox. if Insufficient lubricating oil, please add SAE EP (extremely pressure) 90W oil until the oil level reaches (submerged) Horizontal shaft in gearbox (the axis is parallel to the cover).

NOTE: If the gearbox is fully Drain the oil, about 5 fl. oz (15 cl) oil per gearbox to refill the gear drive components.

Note: Due to the gearbox

It is connected as a unit by connecting pipes, so it is necessary to add Grease slowly. Wait a few minutes after adding oil , allowing the oil to flow throughout the assembly, and Allow oil level to stabilize before reassembly.

Important: Do not overfill the Lawn Mower Gearbox. The gearbox assembly has no exhaust. Filling up the fuel can cause excessive pressure , resulting in an oil leak.

5. Check the condition of the cover gasket, Replace if worn or damaged. Reinstall the transmission cover ;Tighten the screws to 24 in-lb (2.7 N⋅m).

PTO Shafts for Agricultural Gearboxes are Available.

Agricultural equipment includes a variety of PTO shafts. Each 1 is connected by yokes at each end and rotates between 540 and 1,000 rpm. A safety shield is commonly installed on both ends of a PTO shaft to protect the operator. These protective shields are also found in tractors and agricultural implements, and they ensure maximum efficiency. Added safety is also provided by the use of internal yokes.

The agricultural PTO gearbox is designed to change the output speed of a PTO tractor drive shaft. It can be used as a decreasing or increasing ratio gearbox. With the decrease ratio gearbox, it reduces the PTO shaft’s speed from 1000 rpm to 540 rpm, allowing you to use equipment designed for 540 rpm. On the other hand, an increasing ratio gearbox increases the speed of the PTO shaft from 540 rpm to 1000 rpm.

Customized service of agricultural gearbox

Our Lawn Mower Gearbox has many items for your choice and we can produce as per your drawing or sample to meet your special request.

Other Agricultural Gearboxes

Agricultural Gearbox Production Workshop

Hangzhou Ever-power Transmission Machinery Co., Ltd. was established in 2006. The company is located in Zhejiang Hangzhou, with 90 employees, an area of 3800 meters, and an annual output value of 40 million yuan. The company is committed to the R & D, manufacturing, and personnel training of various gearboxes, reducers, and construction machinery, including spiral bevel gearbox, spur gearbox, worm gearbox, and cylindrical gearbox. It also includes a variety of high-pressure cast valve body and shell products. Its products are used in various applications, such as agricultural mowers, snow sweepers, fertilizer applicators, grain conveyors, industrial equipment, oil mining machinery, marine industrial equipment, and engineering hydraulic components. More than 95% of its products are exported to Europe, the United States, and Australia. Asia and Canada. The company has strong technology and R & D capabilities, produces reliable and high-quality products, pursues a unique business philosophy and enjoys a high reputation in the manufacturing industry. Welcome to contact us by phone or email.

China factory EP-140 Agricultural Lawn Mower Gearbox near me supplier

EP-140 Agricultural Lawn Mower Gearbox

The same is true when you’re moving in wet, muddy conditions. You need a lawnmower that lets you traverse obstacles, not just spin the wheels, or get you stuck on slopes. You need a lot of power and torque to move while maintaining grip. However, when you accelerate, you need less torque to keep going.

The lawnmower transmission transmits power from the engine to the wheels and is responsible for managing the speed of the vehicle by changing its torque according to conditions.

| ITEM | EP-140 |

| Ratio | 1:1.5/1:1.93 |

| Teeth | 21/14 27/14 |

| Module | 5.7 /5.64 |

| Power(HP) | 60 |

| Rated Input | 540rpm |

| Input/Output Description | 1-3/8 Z6 Taper spline |

| Weight(N.W) | 30KG |

How To Change Lawn Mower Gearbox Oil?

Mower manufacturers typically use 20W-50 oil in the transmission. In hydrostatic transmissions, there is a better alternative to oil. The oil in the mower hydrostatic transmission will handle the load well.

Hydro-Gear transmissions and pumps should be fluided with either 20W-50 synthetic motor oil or 15W-50 motor oil. It is easy to access and check oil levels on machines with oil reservoirs, as they are mounted to the frame behind the seat.

You should add a few drops of SAE 30 motor oil to each pivot point on the linkage to ensure that it is working properly. The brake pedal, clutch, and lift linkage should be included. The Minnesota Department of Agriculture recommends lubricating the riding mower every 10 hours of use and storing it away after mowing.

Oil changes are usually required every 30,000 to 50,000 miles (48,000 to 80,000 km) for manual gearboxes. If you want to replace your gearbox oil filter, do so at the same time. Changing your oil after a gearbox leak has been repaired is the best way to ensure it is fully topped up.

Changing the gearbox oil yourself requires the same criteria for disposal as changing engine oil. It is not a good idea to dispose of the drained oil in the trash, as it is chemical waste.

The average car can reach 80,000 miles before it needs a gear oil change in normal driving conditions. Insufficiently lubrication can cause serious damage to your gearbox, transfer case, or differentials when contaminated oil is used. In addition, if your transfer case or differentials have recently been repaired, you should replace the gear oil.

The transmission dipstick should be located in the owner’s manual (the location should be shown)….

The dipstick should be pulled out of the filler tube…

Make sure the oil is in the right color.

What Kind Of Oil Do You Put In A Lawn Mower Gearbox?

It is common for mower manufacturers to use 20W-50 motor oil in their transmissions. There is a better alternative to motor oil in hydrostatic transmissions.

PTO Shafts for Agricultural Gearboxes are Available.

Agricultural equipment includes a variety of PTO shafts. Each 1 is connected by yokes at each end and rotates between 540 and 1,000 rpm. A safety shield is commonly installed on both ends of a PTO shaft to protect the operator. These protective shields are also found in tractors and agricultural implements, and they ensure maximum efficiency. Added safety is also provided by the use of internal yokes.

The agricultural PTO gearbox is designed to change the output speed of a PTO drive shaft. It can be used as a decreasing or increasing ratio gearbox. With the decrease ratio gearbox, it reduces the PTO shaft’s speed from 1000 rpm to 540 rpm, allowing you to use equipment designed for 540 rpm. On the other hand, an increasing ratio agricultural gearbox increases the speed of the PTO shaft from 540 rpm to 1000 rpm.

Usage Scenario of Lawn Mower Gearbox

Other Agricultural Gearboxes

Agricultural Gearbox Production Workshop

Hangzhou Ever-power Transmission Machinery Co., Ltd. was established in 2006. The company is located in Zhejiang Hangzhou, with 90 employees, an area of 3800 meters, and an annual output value of 40 million yuan. The company is committed to the R & D, manufacturing, and personnel training of various gearboxes, reducers, and construction machinery, including spiral bevel gearbox, spur gearbox, worm gearbox, and cylindrical gearbox. It also includes a variety of high-pressure cast valve body and shell products. Its products are used in various applications, such as agricultural mowers, snow sweepers, fertilizer applicators, grain conveyors, industrial equipment, oil mining machinery, marine industrial equipment, and engineering hydraulic components. More than 95% of its products are exported to Europe, the United States, and Australia. Asia and Canada. The company has strong technology and R & D capabilities, produces reliable and high-quality products, pursues a unique business philosophy and enjoys a high reputation in the manufacturing industry. Welcome to contact us by phone or email.

China best RV+RV Double Worm Gearbox for Chain Drive wholesaler

Solution Description

Solution Description

Primary Supplies:

1)housing:aluminium alloy ADC12(dimension 571-090) die solid iron HT200(dimensions a hundred and ten-one hundred fifty)

2)Worm:20Cr, ZI Involute profile carbonize&quencher heat therapy make equipment floor hardness up to 56-62 HRC After precision grinding, carburization layer’s thickness amongst .3-.5mm.

3)Worm Wheel:wearable stannum alloy CuSn10-one

Comprehensive Photographs

Mixture Choices:

Input:with input shaft, With sq. flange,With IEC regular input flange

Output:with torque arm, output flange, one output shaft, double output shaft, plastic go over

Worm reducers are accessible with diffferent mixtures: NMRV+NMRV, NMRV+NRV, NMRV+Computer, NMRV+UDL, NMRV+MOTORS

Exploded View:

Solution Parameters

| Outdated Model |

New Model | Ratio | Center Distance | Energy | Input Dia. | Output Dia. | Output Torque | Fat |

| RV571 | 7.5~100 | 25mm | .06KW~.12KW | Φ9 | Φ11 | 21N.m | .7kgs | |

| RV030 | RW030 | seven.5~100 | 30mm | .06KW~.25KW | Φ9(Φ11) | Φ14 | 45N.m | one.2kgs |

| RV040 | RW040 | seven.5~100 | 40mm | .09KW~.55KW | Φ9(Φ11,Φ14) | Φ18(Φ19) | 84N.m | two.3kgs |

| RV050 | RW050 | 7.5~one hundred | 50mm | .12KW~1.5KW | Φ11(Φ14,Φ19) | Φ25(Φ24) | 160N.m | three.5kgs |

| RV063 | RW063 | 7.5~100 | 63mm | .18KW~2.2KW | Φ14(Φ19,Φ24) | Φ25(Φ28) | 230N.m | six.2kgs |

| RV075 | RW075 | seven.5~one hundred | 75mm | .25KW~4.0KW | Φ14(Φ19,Φ24,Φ28) | Φ28(Φ35) | 410N.m | 9.0kgs |

| RV090 | RW090 | seven.5~a hundred | 90mm | .37KW~4.0KW | Φ19(Φ24,Φ28) | Φ35(Φ38) | 725N.m | 13.0kgs |

| RV110 | RW110 | seven.5~a hundred | 110mm | .55KW~7.5KW | Φ19(Φ24,Φ28,Φ38) | Φ42 | 1050N.m | 35.0kgs |

| RV130 | RW130 | seven.5~one hundred | 130mm | .75KW~7.5KW | Φ24(Φ28,Φ38) | Φ45 | 1550N.m | 48.0kgs |

| RV150 | RW150 | 7.5~one hundred | 150mm | 2.2KW~15KW | Φ28(Φ38,Φ42) | Φ50 | 84.0kgs |

GMRV Define Dimension:

| GMRV | A | B | C | C1 | D(H8) | E(h8) | F | G | G1 | H | H1 | I | M | N | O | P | Q | R | S | T | BL | β | b | t | V |

| 030 | 80 | 97 | fifty four | 44 | fourteen | 55 | 32 | 56 | 63 | 65 | 29 | 55 | 40 | fifty seven | 30 | 75 | forty four | six.five | 21 | five.five | M6*ten(n=4) | 0° | five | sixteen.three | 27 |

| 040 | a hundred | 121.five | 70 | sixty | 18(19) | 60 | 43 | 71 | seventy eight | 75 | 36.five | 70 | 50 | 71.five | 40 | 87 | fifty five | 6.five | 26 | 6.5 | M6*ten(n=4) | 45° | 6 | twenty.8(21.8) | 35 |

| 050 | one hundred twenty | a hundred and forty four | 80 | 70 | 25(24) | 70 | 49 | 85 | 92 | eighty five | 43.5 | 80 | sixty | eighty four | 50 | a hundred | sixty four | 8.five | thirty | 7 | M8*twelve(n=4) | 45° | 8 | 28.3(27.3) | forty |

| 063 | one hundred forty four | 174 | one hundred | 85 | 25(28) | eighty | 67 | 103 | 112 | 95 | 53 | 95 | 72 | 102 | 63 | 110 | eighty | 8.five | 36 | eight | M8*twelve(n=8) | 45° | eight | 28.3(31.3) | fifty |

| 075 | 172 | 205 | a hundred and twenty | ninety | 28(35) | ninety five | seventy two | 112 | a hundred and twenty | one hundred fifteen | 57 | 112.five | 86 | 119 | seventy five | one hundred forty | ninety three | eleven | 40 | ten | M8*14(n=8) | 45° | eight(ten) | 31.3(38.3) | 60 |

| 090 | 206 | 238 | one hundred forty | 100 | 35(38) | one hundred ten | 74 | a hundred thirty | one hundred forty | one hundred thirty | sixty seven | 129.five | 103 | one hundred thirty five | ninety | 160 | 102 | thirteen | 45 | eleven | M10*sixteen(n=8) | 45° | 10 | 38.3(forty one.3) | 70 |

| a hundred and ten | 255 | 295 | 170 | one hundred fifteen | forty two | 130 | – | a hundred and forty four | a hundred and fifty five | 165 | seventy four | one hundred sixty | 127.five | 167.five | 110 | 200 | one hundred twenty five | 14 | 50 | fourteen | M10*18(n=8) | 45° | 12 | 45.three | 85 |

| one hundred thirty | 293 | 335 | 200 | one hundred twenty | 45 | 180 | – | one hundred fifty five | one hundred seventy | 215 | 81 | 179 | 146.five | 187.five | 130 | 250 | one hundred forty | sixteen | sixty | 15 | M12*20(n=8) | 45° | 14 | forty eight.eight | one hundred |

| 150 | 340 | four hundred | 240 | 145 | 50 | a hundred and eighty | – | 185 | two hundred | 215 | 96 | 210 | a hundred and seventy | 230 | 150 | 250 | 180 | eighteen | 72.five | eighteen | M12*22(n=8) | 45° | fourteen | fifty three.8 | 120 |

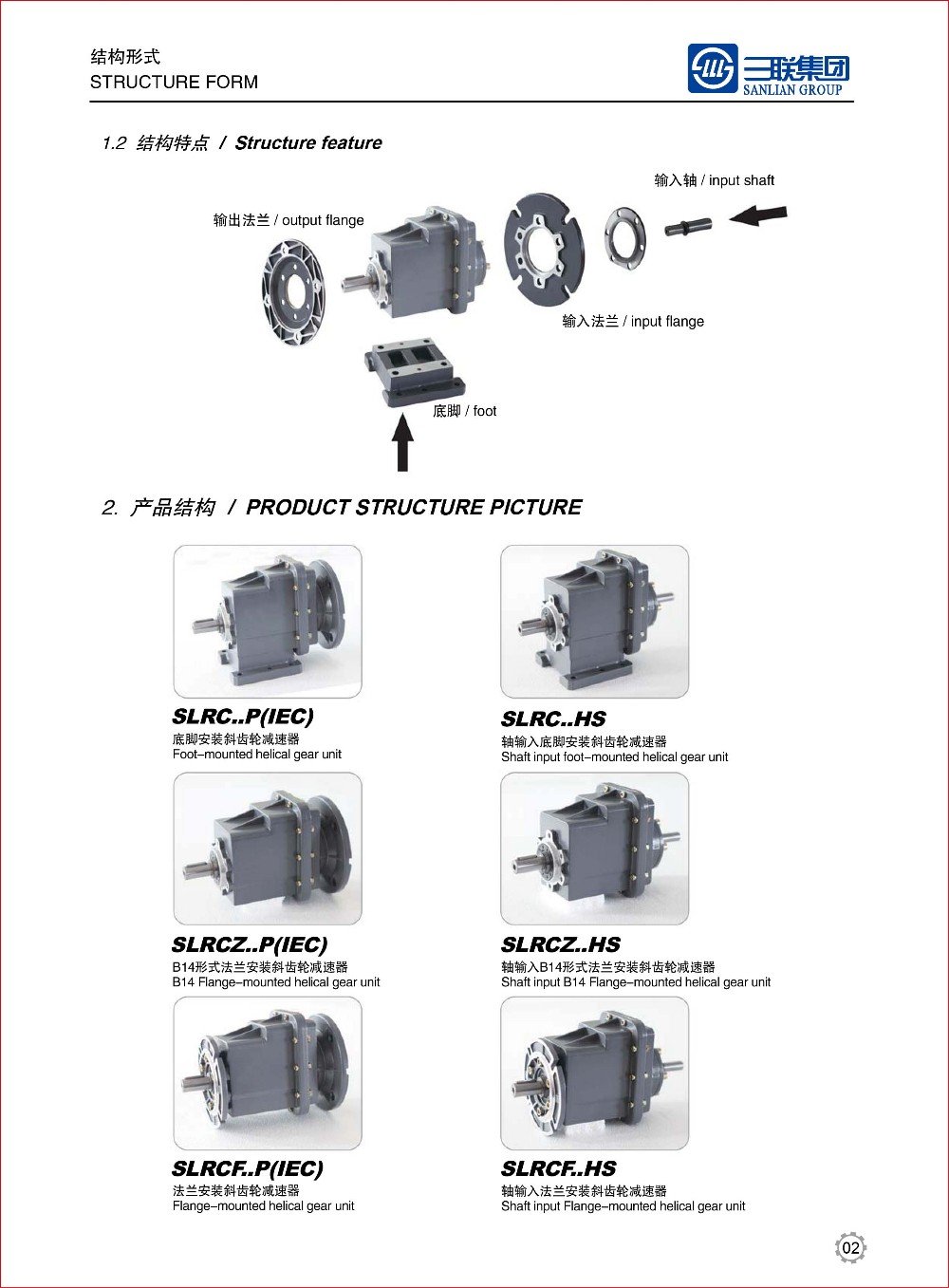

Firm Profile

About CZPT Transmission:

We are a professional reducer company situated in HangZhou, ZHangZhoug province.

Our major products is full selection of RV571-one hundred fifty worm reducers , also provided GKM hypoid helical gearbox, GRC inline helical gearbox, Pc models, UDL Variators and AC Motors, G3 helical gear motor.

Products are widely utilized for purposes these kinds of as: foodstuffs, ceramics, packing, chemical compounds, pharmacy, plastics, paper-generating, design equipment, metallurgic mine, environmental defense engineering, and all types of automated lines, and assembly lines.

With fast shipping and delivery, superior right after-income provider, sophisticated making facility, our products sell well both at home and overseas. We have exported our reducers to Southeast Asia, Japanese Europe and Middle East and so on.Our intention is to create and innovate on basis of substantial good quality, and generate a good status for reducers.

Packing details:Plastic Bags+Cartons+Wood Cases , or on ask for

We participate Germany Hannver Exhibition-ZheJiang PTC Truthful-Turkey Earn Eurasia

Logistics

Following Product sales Support

1.Routine maintenance Time and Warranty:Inside of 1 12 months following obtaining merchandise.

two.Other Support: Like modeling variety guide, set up guidebook, and issue resolution manual, etc.

FAQ

one.Q:Can you make as per customer drawing?

A: Yes, we offer tailored support for customers accordingly. We can use customer’s nameplate for gearboxes.

two.Q:What is your phrases of payment ?

A: 30% deposit ahead of manufacturing,harmony T/T prior to delivery.

three.Q:Are you a trading business or producer?

A:We are a manufacurer with innovative gear and knowledgeable staff.

4.Q:What’s your manufacturing capacity?

A:8000-9000 PCS/Thirty day period

five.Q:Free of charge sample is accessible or not?

A:Sure, we can source totally free sample if buyer concur to spend for the courier expense

6.Q:Do you have any certificate?

A:Sure, we have CE certificate and SGS certification report.

Contact data:

Ms Lingel Pan

For any questions just really feel totally free ton contact me. Numerous many thanks for your kind consideration to our organization!

Whether you are constructing from scratch or updating an current undertaking, finding the proper dimension for your roller chain is a vital first determination. To correctly measure a roller chain, you need to know the overall width, diameter, and width of the rollers, plate thickness, and peak.

The push chain is employed to transmit mechanical electricity when the axle distance is limited. These chains have successful lubrication. There are the subsequent a few sorts of electrical power transmission chains. Slider or Bushing Chain Bushing Roller Chain Quiet Chain

China Hot selling Chain Drive Reduction Double Worm Gearbox with Great quality

Merchandise Description

RV collection Characteristics

- RV – Dimensions:030-040-050-063-075-a hundred and five-a hundred and ten-130-a hundred and fifty

- Input Choices: with input shaft, With Square flange,With Enter Flange

- Input Energy .06 to 11 kW

- RV-Dimension from 030 to 105 in die-solid aluminium alloy budy and more than one hundred ten in solid iron

- Ratios among 5 and a hundred

- Max torque 1550 N.m and admissible output radial masses max 8771 N

- Aluminium models are supplied full with artificial oil and allow for universal mounting positions, with no need to modify CZPT amount

- Worm wheel: Copper (KK Cu).

- Loading capacity in accordance with: ISO 9001:2015/GB/T 19001-2016

- Measurement 030 and over are painted with RAL 5571 blue

- Worm equipment reducers are obtainable with diffferent combinations: NMRV+NMRV, NMRVpower+NMRV, JWB+NMRV

- NMRV, NRV+VS,NMRV+AS,NMRV+VS,NMRV+F

- Alternatives: torque arm, output flange, viton oil seals, lower/large temperature oil, filling/drain/breather/amount plug,Little gap

Standard types can be used to a broad variety of energy reduction ratios from 5 to 1000.

Guarantee: One year from day of delivery.

| WORM GEARBOX | |||||

| SNW SERIES | Output Pace Selection: | ||||

| Sort | Old Variety | Output Torque | Output Shaft Dia. | 14rpm-280rpm | |

| SNW030 | RV030 | 21N.m | φ14 | Applicable Motor Electricity: | |

| SNW040 | RV040 | 45N.m | φ19 | .06kW-11kW | |

| SNW050 | RV050 | 84N.m | φ25 | Input Options1: | |

| SNW063 | RV063 | 160N.m | φ25 | With Inline AC Motor | |

| SNW075 | RV075 | 230N.m | φ28 | Enter Options2: | |

| SNW090 | RV090 | 410N.m | φ35 | With Square flange | |

| SNW105 | RV105 | 630N.m | φ42 | Input Options3: | |

| SNW110 | RV110 | 725N.m | φ42 | With Enter Shaft | |

| SNW130 | RV130 | 1050N.m | φ45 | Input Options4: | |

| SNW150 | RV150 | 1550N.m | φ50 | With Enter Flange |

Starshine Drive

ZheJiang Starshine Drive Co.,Ltd,the predecessor was proven in 1965. Starshine specializes in the comprehensive electricity transmission resolution for substantial-conclude tools producing industries based mostly on the intention of “Platform Item, Application Design and Specialist Service”.

Starshine have a powerful technical force with more than 350 employees at current, including over 30 engineering specialists, 30 good quality inspectors, masking an spot of 80000 square meters and types of sophisticated processing machines and tests equipments. We have a very good basis for the sector software improvement and service of large-conclude pace reducers & variators possessing to the provincial engineering technological innovation investigation middle,the lab of equipment velocity reducers, and the base of CZPT R&D.

Our Crew

Top quality Management

Quality:Insist on Improvement,Strive for Excellence With the development of equipment manufacturing indurstry,customer never satirsfy with the current quality of our products,on the contrary,wcreate the value of quality.

Quality policy:to enhance the overall level in the field of power transmission

Quality View:Continuous Improvement , pursuit of excellence

Quality Philosophy:Quality creates value

3. Incoming Quality Control

To establish the AQL acceptable level of incoming material control, to provide the material for the whole inspection, sampling, immunity. On the acceptance of qualified products to warehousing, substandard goods to take return, check, rework, rework inspection responsible for tracking bad, to monitor the supplier to take corrective measures

to prevent recurrence.

4. Process Quality Control

The manufacturing site of the first examination, inspection and final inspection, sampling according to the requirements of some projects, judging the quality change trend

found abnormal phenomenon of manufacturing, and supervise the production department to improve, eliminate the abnormal phenomenon or state.

5. FQC(Final QC)

After the manufacturing department will complete the product, stand in the customer’s position on the finished product quality verification, in order to ensure the quality of

customer expectations and needs.

6. OQC(Outgoing QC)

After the product sample inspection to determine the qualified, allowing storage, but when the finished product from the warehouse before the formal delivery of the goods, there is a check, this is called the shipment inspection.Check content:In the warehouse storage and transfer status to confirm, while confirming the delivery of the product

is a product inspection to determine the qualified products.

Packing

Delivery

This type of chain is employed in the initial phases of electrical power transmission growth. When the sprocket moves nearer to or absent from the teeth, noise is created as the enamel rub from the connecting rod. These sorts of chains are used to some extent for minimal-speed conveyor chains.

Silent chain, also known as inverted tooth chain. It is developed to remove the ill consequences of stretching and develop a tranquil stroll. As the chain is stretched and the pitch of the chain raises, the radius that the chainrings vacation over the sprocket tooth boosts a bit.

Custom made in China – replacement parts – in Penza Russian Federation Steel High Quality Small Spur Sun Gear for Planetary Gearbox with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 diverse branches. For more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Product Data

Equipment transmission refers to the unit that transmits motion and power from the gear pair. It is the mo EPT commonly utilised mechanical transmission approach in modern gear. Its transmission is more precise, large effectiveness, compact composition, trustworthy procedure and lengthy support daily life.

Our gears can be warmth handled, hardened, oil immersed according to client wants.

The equipment is commonly utilised in industry, car, power equipment, motor, bicycle, electrombile.

|

|

We can make customers’ satisfactory merchandise in accordance to the samples or drawings presented by clients. For the completion of a solution, we also want to know his substance, heat therapy requirements and surface area remedy needs. We are a manufacturing unit with forty a long time of manufacturing knowledge, welcome to seek the advice of.

Our business focus in making all sorts of internal and exterior equipment, higher precision spline shaft and equipment shaft. We are looking forward to the cooperation with you, and we imagine that we will be your best decision.

FAQ

one)Are you investing business or maker?

We are manufacturing unit.

2)How can I personalize my items?

Attach your drawing with particulars(floor treatment,content,amount and particular needs etc.)

three)How lengthy can I get the quotation?

We will give you the quotation inside 48 several hours(contemplating the time distinction)

4)How prolonged will you make the parts?

Normally it is 5-10 times if the products are in stock. Or it is 15-25 days if the merchandise are not in stock, it’s in accordance to amount.

five)Do you supply samples? Is it totally free or added?

Indeed, we could offer you the sample, the samples and shipping expenses require to be borne by the shopper.

6)What is your terms of payment?

Payment≤1000 USD, a hundred% in advance. Payment≥1000 USD, 30% T/T in progress, stability prior to shipment. If you have any queries, make sure you don’t be reluctant to make contact with us.

seven)What if the items we obtained are not excellent?

Contact us without hesitation, our specific soon after-revenue service will take the responsibility.

The use of unique gear manufacturer’s (OEM) component numbers or trademarks , e.g. CASE® and John Deere® are for reference needs only and for indicating merchandise use and compatibility. Our company and the detailed alternative parts contained herein are not sponsored, approved, or produced by the OEM.

Best China manufacturer & factory Stubble in Gaya India Cleaner Gearbox With high quality best price

Entire use has been made of all varieties of sophisticated techniques and technology to reach excelsior producing.

Overview

Fast Specifics

- Relevant Industries:

-

Producing Plant, Equipment Mend Outlets, Farms

- Brand Identify:

-

OEM

- Gearing Arrangement:

-

Spur

- Output Torque:

-

108.7Nm

- Input Speed:

-

540rpm

- Output Speed:

-

Environmentally friendly company, the organization accountable

Ratio1.ninety two:1

- Model Number:

-

XH45.192J.04W

- Rated Electrical power:

-

45HP

-

A power take-off or power takeoff (PTO) is any of a number of strategies for using energy from a electricity supply, these kinds of as a running motor, and transmitting it to an application these kinds of as an attached put into action or individual machine.

- ratio (i):

-

one.ninety two:1

- bodyweight:

-

23 kg

Offer Capacity

- Source Capacity:

- 20000 Piece/Pieces for each Yr or much more

Packaging & Shipping

- Packaging Particulars

- (dimension:1120*1050*740 mm)”>wooden situation ideal for exportation

(dimension:1120*1050*740 mm)

- Port

- Shanghai and so forth.

-

Guide Time

: -

Amount(Pieces) 1 – 2000 >2000 Est. Time(times) forty five To be negotiated

On-line Customization

Stubble Cleaner Gearbox

The sequence gearboxes have the attributes of universality, easy framework, very good overall performance, et. By means of ongoing practice and huge production for a lot of a long time, it has shaped many sequence with numerous kinds of merchandise, which has been exported into abroad marketplaces in Europe and The usa, and is suitable to consumers.

| Code | Input Electrical power (HP) |

Enter Speed (r.p.m.) |

Equipment Ratio (i) |

Output Torque (da Nm) |

Fat (kg) |

| XH20.300J.twelve | twenty | 540 | three:one | 75.6 | 16 |

| XH20.300J.02 | twenty | 540 | 3:1 | 75.6 | 16 |

| XH21.283Z.01L | 21 | 540 | one:2.83 | nine.four | 15.5 |

| XH23.146J.02W | 23 | 540 | 1.46:one | 41 | seven.five |