Product Description

Product Description

KASIN intermediate carrier chains operate in the most corrosive conditions brought about by continous operation in raw sugar juice.As a consquence chains employ corrosion resistant materials . The swivel attachments allows for self allignment of the strands during operation compensating for anymismatch.

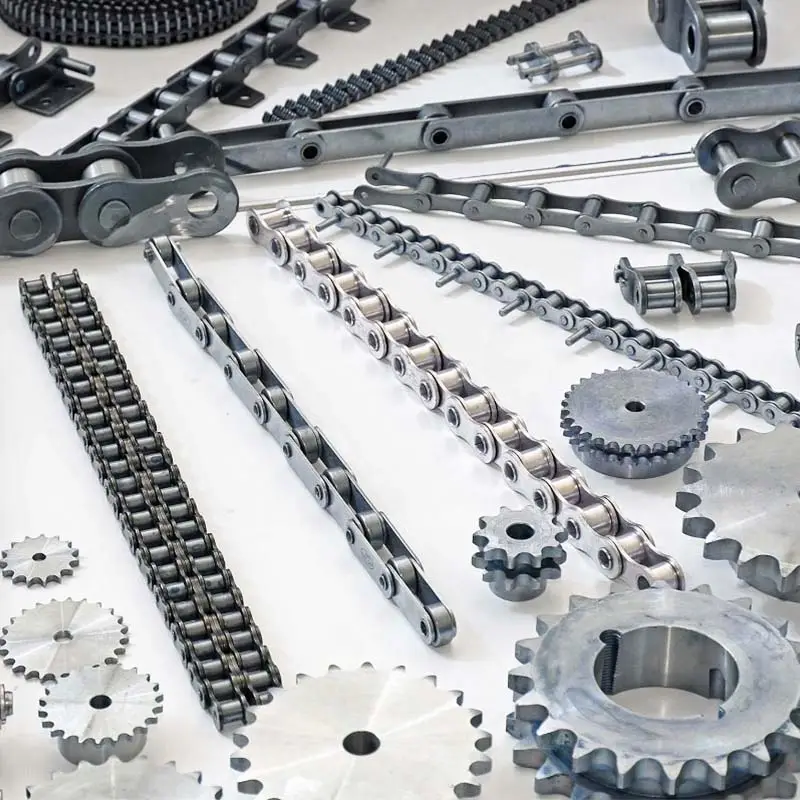

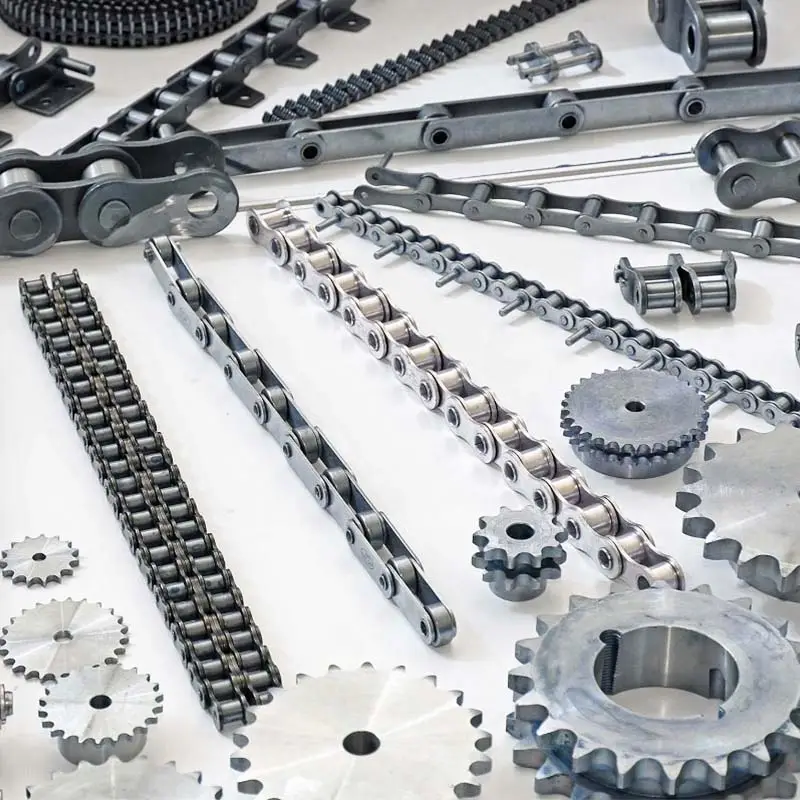

Related Products

About Us

Kasin group was established in 1989, and its first product is casting carrier trolley for power & free conveyor system. In 1995, CHINAMFG purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to power & free line market in china. With this acquisition, CHINAMFG positioned itself as 1 of major parts suppliers of monorail and power & free conveyor system in china.

In 2

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy |

|---|---|

| Structure: | Roller Chain |

| Surface Treatment: | Polishing |

| Feature: | Fire Resistant, Oil Resistant, Heat Resistant |

| Pitch: | 101.60mm |

| Roller Dia: | 50.80mm |

| Samples: |

US$ 100/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can engineering chains be repaired or must they be completely replaced?

Unlike some other components, engineering chains are generally not designed to be repaired. Once an engineering chain shows signs of wear, damage, or elongation, it is recommended to replace the entire chain rather than attempting repairs. Here are the reasons why engineering chains are typically replaced instead of repaired:

1. Safety Concerns: Engineering chains are critical components in industrial applications, often responsible for transmitting high loads and operating at high speeds. If a chain fails due to a repair that was not performed correctly, it can lead to serious safety hazards and potential accidents.

2. Complex Design: Engineering chains have a complex design with various components, including pins, rollers, bushings, and plates. Repairing these components and restoring them to their original specifications is difficult and may not guarantee the same level of performance and reliability as a new chain.

3. Cost-Effectiveness: In many cases, repairing an engineering chain can be more costly and time-consuming than simply replacing it. Additionally, a repaired chain may have a shorter service life, leading to more frequent replacements in the future.

4. System Integrity: Engineering chains work as part of a larger system, engaging with sprockets and other components. If a repaired chain does not fit perfectly within the system, it can cause misalignment, premature wear, and reduced performance.

5. Manufacturer Recommendations: Chain manufacturers usually recommend replacing the entire chain when it shows signs of wear or elongation. Following these recommendations ensures that the system operates as intended and maintains its reliability.

Considering the critical role of engineering chains in various industrial applications, it is best to prioritize safety, reliability, and system performance by replacing worn or damaged chains with new ones. Regular maintenance, proper lubrication, and timely replacements will help extend the service life of the engineering chains and contribute to the overall efficiency of the machinery and equipment.

What are the benefits of using an engineering chain over other power transmission methods?

Engineering chains offer several advantages over other power transmission methods, making them a preferred choice in various industrial applications:

- High Strength: Engineering chains are designed to handle heavy loads and high torque, making them suitable for demanding applications that require robust and reliable power transmission.

- Wide Range of Sizes: These chains are available in a wide range of sizes and configurations, allowing for flexibility in design and accommodating various application requirements.

- Durable and Long-Lasting: When properly maintained, engineering chains have a long service life, reducing the need for frequent replacements and minimizing downtime in industrial operations.

- Adaptable to Harsh Environments: Engineering chains are capable of operating in harsh conditions, including dusty, dirty, or corrosive environments, without compromising their performance.

- Shock Load Resistance: The design of engineering chains allows them to handle sudden impact forces and shock loads, which can occur in certain industrial processes.

- Cost-Effective: Engineering chains often provide a cost-effective solution for power transmission compared to other methods, especially in high-load applications.

- Simple Installation: With proper alignment and tensioning, engineering chains are relatively easy to install, reducing installation time and labor costs.

- Bi-Directional Power Transmission: Engineering chains can transmit power in both forward and reverse directions, making them suitable for applications requiring bidirectional motion.

- Low Maintenance: Regular maintenance, such as lubrication and inspection, can keep engineering chains in good working condition, reducing overall maintenance costs.

- Reduction of Noise and Vibration: When adequately lubricated and aligned, engineering chains can operate quietly and with minimal vibration, contributing to a more comfortable and safer working environment.

Despite their many advantages, it’s essential to consider the specific requirements of each application before selecting an engineering chain. Factors such as load capacity, speed, environmental conditions, and space constraints should be taken into account to ensure the chain’s optimal performance and longevity.

In summary, engineering chains are a versatile and reliable power transmission method, offering a range of benefits that make them well-suited for use in various industrial settings.

What is an engineering chain and what are its uses in various industries?

An engineering chain, also known as an industrial chain, is a type of power transmission chain widely used in various industries for transmitting mechanical power between two or more rotating shafts. It consists of a series of interconnected links that form a flexible and durable mechanism capable of handling heavy loads and harsh operating conditions. Here are its uses in different industries:

1. Manufacturing Industry:

In the manufacturing sector, engineering chains are employed in conveyor systems for material handling, assembly lines, and automated production processes. They facilitate the movement of raw materials, workpieces, and finished products efficiently, streamlining production and reducing manual labor.

2. Automotive Industry:

Automotive manufacturing relies heavily on engineering chains for conveying car parts during assembly. From the production of engines to body assembly, these chains ensure a smooth and continuous flow of components through the manufacturing process.

3. Agriculture and Farming:

In the agricultural sector, engineering chains are used in machinery such as tractors and combine harvesters. They facilitate power transmission from the engine to different agricultural implements, enabling various tasks like plowing, seeding, and harvesting.

4. Construction and Mining:

Construction equipment and mining machinery utilize engineering chains for heavy-duty power transmission. These chains are suitable for harsh environments and high-load applications, making them ideal for conveying construction materials and excavating operations.

5. Oil and Gas Industry:

In the oil and gas sector, engineering chains are utilized in drilling rigs and oil extraction equipment. They assist in the rotation of drill bits and the transfer of power within complex drilling systems.

6. Food and Beverage Industry:

Engineering chains find applications in food processing and beverage manufacturing, where they are used in conveyor systems for handling ingredients, packaging, and bottling processes. Specialized food-grade chains are designed to meet strict hygiene standards.

7. Material Handling:

Across various industries, engineering chains are widely employed in material handling systems, including overhead cranes, hoists, and elevators. They ensure smooth and efficient movement of heavy loads in warehouses, distribution centers, and manufacturing facilities.

8. Pulp and Paper Industry:

In the pulp and paper industry, engineering chains are used in paper processing machines, pulp digesters, and paper converting equipment. They contribute to the continuous flow of paper products during manufacturing.

9. Renewable Energy:

In the renewable energy sector, engineering chains are utilized in wind turbines and solar tracking systems. They assist in adjusting the position of solar panels and wind turbine blades to optimize energy capture.

10. Power Generation:

In power plants, engineering chains are used in various equipment, including conveyor systems for transporting fuel and ash, as well as in boiler feed systems and other power generation processes.

11. Water and Wastewater Treatment:

Engineering chains are employed in water treatment plants for sludge dewatering and in wastewater treatment plants for handling sludge and screenings.

12. Textile Industry:

In textile machinery, engineering chains assist in the production process, including spinning, weaving, and fabric handling.

13. Printing Industry:

In printing presses, engineering chains facilitate the smooth movement of paper during the printing process.

14. Packaging Industry:

Engineering chains are utilized in packaging machinery for handling boxes, cartons, and other packaging materials.

Overall, engineering chains are versatile components that play a crucial role in various industries for power transmission and material handling applications. They provide reliability, durability, and efficiency, making them an essential part of modern industrial processes.

editor by CX 2024-05-09

China best Ss800–A42 (B) Steel Engineering Class Conveyor Chain for Sugar Mill Roller Chain for Sugar Industry Chains

Product Description

Product Description

KASIN intermediate carrier chains operate in the most corrosive conditions brought about by continous operation in raw sugar juice.As a consquence chains employ corrosion resistant materials . The swivel attachments allows for self allignment of the strands during operation compensating for anymismatch.

Related Products

About Us

Kasin group was established in 1989, and its first product is casting carrier trolley for power & free conveyor system. In 1995, CHINAMFG purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to power & free line market in china. With this acquisition, CHINAMFG positioned itself as 1 of major parts suppliers of monorail and power & free conveyor system in china.

In 2

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy |

|---|---|

| Structure: | Roller Chain |

| Surface Treatment: | Polishing |

| Feature: | Fire Resistant, Oil Resistant, Heat Resistant |

| Pitch: | 203.20mm |

| Roller Dia: | 89.00mm |

| Samples: |

US$ 100/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do engineering chains compare to other types of chains in terms of efficiency?

Engineering chains are known for their high efficiency in power transmission compared to some other types of chains. Their efficiency can be attributed to several factors:

- Minimal Friction: Engineering chains are designed with precision rollers and bushings, which reduces friction between the chain’s components. This results in less energy loss during power transmission.

- High-Quality Materials: These chains are typically made from high-quality materials, such as alloy steel, which ensures durability and minimal elongation under heavy loads. This material choice helps maintain efficiency over extended periods of use.

- Precise Manufacturing: Engineering chains are manufactured with tight tolerances and precise engineering, ensuring consistent performance and smooth operation. This precision minimizes energy losses due to chain misalignment or uneven loading.

- Optimized Design: The design of engineering chains takes into account the specific requirements of power transmission, making them well-suited for their intended applications. This optimized design contributes to their overall efficiency.

- Proper Lubrication: Regular and proper lubrication of engineering chains is essential to maintain their efficiency. Adequate lubrication reduces friction and wear, optimizing power transfer efficiency.

Compared to some other types of chains, such as standard roller chains, engineering chains may offer higher efficiency due to their advanced design and manufacturing processes. However, the choice of chain type depends on the specific application requirements, load conditions, operating environment, and other factors.

In certain applications, other power transmission methods like belts or gears might be preferred over chains, based on factors such as noise level, space constraints, and maintenance considerations. Each power transmission method has its advantages and limitations, and selecting the most suitable option requires careful consideration of the application’s needs.

How do engineering chains handle angular misalignment between sprockets?

Engineering chains are designed to handle a certain degree of angular misalignment between sprockets. Angular misalignment occurs when the rotational axes of the driving and driven sprockets are not perfectly parallel, leading to an angle between them. While it is essential to minimize misalignment to prevent excessive wear and premature failure, some level of misalignment tolerance is built into engineering chains to accommodate real-world installation variations.

When angular misalignment exists, the chain’s side plates and rollers are designed to articulate and adjust to the varying angles between the sprockets. This flexibility allows the chain to smoothly engage and disengage from the sprocket teeth without binding or jamming. However, it’s important to note that excessive misalignment can still cause accelerated wear, noise, and reduced efficiency in the chain drive system.

To ensure optimal performance and longevity, it is recommended to keep angular misalignment within the manufacturer’s specified limits. These limits can vary depending on the chain size, type, and application. When installing an engineering chain, it’s crucial to align the sprockets as accurately as possible and use alignment tools if necessary.

In applications where angular misalignment is unavoidable, special chain types or accessories, such as chain tensioners or idler sprockets, can be used to help compensate for the misalignment and improve overall system performance.

In summary, engineering chains are designed to handle a certain degree of angular misalignment between sprockets, but it is essential to follow the manufacturer’s guidelines and maintain proper alignment to ensure reliable and efficient operation of the chain drive system.

What are the advantages of using an engineering chain in industrial applications?

Engineering chains offer several advantages that make them highly suitable for a wide range of industrial applications:

- Robust and Durable: Engineering chains are built to withstand heavy loads, harsh environmental conditions, and abrasive materials commonly found in industrial settings. Their robust construction ensures long-lasting performance and reduces the frequency of replacements, contributing to cost-effectiveness.

- Versatility: With various types and configurations available, engineering chains are highly versatile. They can be adapted to a wide array of applications, such as material handling, conveyor systems, bucket elevators, and more. Different attachments and accessories further enhance their adaptability for specific tasks.

- Specialized Variants: The market offers a diverse selection of engineering chains with specialty variants designed for specific industries. Whether it’s mining, agriculture, automotive, or food processing, there is likely an engineering chain optimized for the unique demands of each application.

- High Load Capacity: Engineering chains are capable of handling heavy loads, making them suitable for heavy machinery, lifting equipment, and other industrial applications requiring substantial power transmission capabilities.

- Efficient Power Transmission: The design of engineering chains ensures smooth and efficient power transmission, reducing energy losses and improving overall system performance.

- Attachments and Accessories: Many engineering chains come with pre-installed or customizable attachments that enable them to perform specialized tasks. These attachments can include slats, buckets, rollers, and other components, enhancing their ability to carry, grip, or convey materials as needed.

- Reliable Performance: Due to their robust design and precise engineering, these chains provide reliable and consistent performance even under challenging conditions, contributing to increased productivity and reduced downtime.

- Wide Range of Materials: Engineering chains can be manufactured from various materials, including carbon steel, stainless steel, and plastic, allowing for compatibility with different operating environments and industries.

- Cost-Effective Solutions: Despite their higher initial cost compared to standard roller chains, engineering chains often prove to be cost-effective in the long run due to their extended service life and reduced maintenance needs.

In summary, engineering chains offer durability, versatility, and specialized features that make them an excellent choice for industrial applications where reliable and efficient power transmission is essential. Their ability to handle heavy loads, varied environments, and specific tasks sets them apart as a valuable component in numerous industrial processes.

editor by CX 2024-05-02

China high quality Ss1796 Hyper -K2 Steel Engineering Class Conveyor Chain for Sugar Mill Roller Chain for Sugar Industry Chains

Product Description

Product Description

KASIN intermediate carrier chains operate in the most corrosive conditions brought about by continous operation in raw sugar juice.As a consquence chains employ corrosion resistant materials . The swivel attachments allows for self allignment of the strands during operation compensating for anymismatch.

Related Products

About Us

Kasin group was established in 1989, and its first product is casting carrier trolley for power & free conveyor system. In 1995, CHINAMFG purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to power & free line market in china. With this acquisition, CHINAMFG positioned itself as 1 of major parts suppliers of monorail and power & free conveyor system in china.

In 2

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy |

|---|---|

| Structure: | Roller Chain |

| Surface Treatment: | Polishing |

| Feature: | Fire Resistant, Oil Resistant, Heat Resistant |

| Pitch: | 152.40mm |

| Roller Dia: | 76.20mm |

| Samples: |

US$ 100/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can engineering chains be used in overhead or inverted applications?

Yes, engineering chains can be used in both overhead and inverted applications, provided they are properly selected and installed. These types of applications are common in various industries, including material handling, automotive, and food processing. Engineering chains are versatile and well-suited for such applications due to their robust construction, flexibility, and ability to handle heavy loads.

Overhead applications involve suspending the chain from overhead beams or structures, while inverted applications require the chain to run on the underside of the conveyor or equipment. Some factors to consider when using engineering chains in these applications include:

- Corrosion Resistance: For overhead applications in outdoor environments or areas with exposure to moisture, it is essential to use engineering chains made from corrosion-resistant materials, such as stainless steel, to prevent rust and ensure longevity.

- Lubrication: Proper and regular lubrication is crucial for chains in both overhead and inverted applications to reduce friction, wear, and noise levels. Lubrication also helps protect the chain from contaminants and moisture.

- Load Capacity: Ensure that the engineering chain selected has a sufficient load capacity to handle the weight of the conveyed materials or equipment in the application.

- Installation: Proper installation is critical for the smooth operation of the chain in overhead and inverted applications. Correct tensioning and alignment will help prevent premature wear and improve overall performance.

- Chain Speed: Consider the speed at which the chain will be running in the application, as higher speeds may require additional considerations in terms of lubrication and wear.

By taking these factors into account and following the manufacturer’s guidelines for installation, lubrication, and maintenance, engineering chains can be used effectively in overhead and inverted applications. They offer reliable and efficient power transmission and material handling solutions, making them valuable components in a wide range of industrial processes and systems.

How do engineering chains handle side loads and lateral forces?

Engineering chains are designed to handle side loads and lateral forces effectively, making them suitable for applications where such forces may be present. The ability of engineering chains to handle side loads and lateral forces is primarily influenced by their construction and material properties.

Key factors contributing to the handling of side loads and lateral forces by engineering chains include:

- Chain Design: Engineering chains are often constructed with solid bushings and rollers that provide smooth articulation between the chain links. This design minimizes friction and wear, allowing the chain to better accommodate lateral movements.

- Material Selection: High-quality engineering chains are typically made from durable materials, such as alloy steel, that offer excellent tensile strength and resistance to fatigue. These material properties enable the chain to withstand lateral forces without deformation or failure.

- Clearances: The clearances between the chain components and the sprocket teeth are carefully engineered to ensure that the chain can flex and adjust to lateral forces without jamming or binding. Proper clearances also help reduce wear and noise during operation.

- Guidance Systems: In certain applications, additional guidance systems may be used to support the chain and maintain its alignment, especially when dealing with significant side loads. These guidance systems can include wear strips, guide rails, or other forms of lateral support.

It’s important to note that while engineering chains can handle some degree of side loads and lateral forces, excessive or prolonged lateral forces can lead to premature wear and reduced chain life. Therefore, it is crucial to select the appropriate chain size and design for the specific application and operating conditions to ensure optimal performance and longevity.

Regular maintenance, including proper lubrication and periodic inspection, is also essential to monitor chain wear and detect any signs of damage that may result from side loads or other external forces. By following proper maintenance practices, the engineering chain’s ability to handle side loads and lateral forces can be maximized, ensuring reliable and efficient power transmission in various industrial applications.

Can engineering chains handle heavy loads and high torque requirements?

Yes, engineering chains are designed to handle heavy loads and high torque requirements, making them well-suited for various industrial applications that demand robust power transmission capabilities. The construction and materials used in engineering chains ensure their ability to withstand the stresses and forces associated with heavy loads and high torque.

Engineering chains are commonly used in heavy machinery, mining equipment, construction machinery, and other applications where substantial power transmission is necessary. Their sturdy design and precise engineering allow them to efficiently transmit power and handle the forces generated during operation.

The load capacity and torque-handling capabilities of engineering chains can vary depending on their design, size, and material. Manufacturers provide technical specifications and load ratings for different engineering chain types, enabling users to select the appropriate chain based on their specific application requirements.

In summary, engineering chains are well-equipped to handle heavy loads and high torque requirements, making them reliable and effective components in industrial systems that demand strength, durability, and efficient power transmission.

editor by CX 2024-04-24

China Standard 0904-a Steel Engineering Class Conveyor Chain for Sugar Mill Roller Chain for Sugar Industry Chains

Product Description

Product Description

KASIN intermediate carrier chains operate in the most corrosive conditions brought about by continous operation in raw sugar juice.As a consquence chains employ corrosion resistant materials . The swivel attachments allows for self allignment of the strands during operation compensating for anymismatch.

Related Products

About Us

Kasin group was established in 1989, and its first product is casting carrier trolley for power & free conveyor system. In 1995, CHINAMFG purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to power & free line market in china. With this acquisition, CHINAMFG positioned itself as 1 of major parts suppliers of monorail and power & free conveyor system in china.

In 2

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy |

|---|---|

| Structure: | Roller Chain |

| Surface Treatment: | Polishing |

| Feature: | Fire Resistant, Oil Resistant, Heat Resistant |

| Pitch: | 101.60mm |

| Roller Dia: | 50.80mm |

| Samples: |

US$ 100/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can engineering chains be used in high-temperature environments?

Yes, engineering chains can be used in high-temperature environments, but their performance depends on the type of material they are made of and the specific temperature conditions they are exposed to. Here are some considerations for using engineering chains in high-temperature environments:

- Material Selection: Chains made from heat-resistant materials, such as stainless steel or special alloy steels, are suitable for high-temperature applications. These materials offer increased resistance to heat, oxidation, and corrosion.

- Lubrication: Proper lubrication is critical when using engineering chains in high-temperature environments. High-temperature lubricants that can withstand the specific temperature range are essential to reduce friction and wear between the chain’s components.

- Heat Dissipation: In high-temperature environments, the heat generated by the chain’s operation needs to be dissipated effectively to prevent excessive temperature rise. Adequate ventilation or cooling mechanisms may be required to maintain the chain within a safe operating temperature range.

- Chain Design: Chains intended for high-temperature use may have specific design features that enhance their heat resistance and performance. These design modifications can include heat-resistant coatings, special alloys, or heat-treated components.

- Operating Conditions: The operating conditions, such as the temperature range and the duration of exposure to high temperatures, should be carefully evaluated to ensure the chain’s material and lubrication are suitable for the specific application.

- Inspections and Maintenance: Regular inspections and maintenance are crucial to monitor the chain’s condition and performance in high-temperature environments. Any signs of wear, elongation, or damage should be addressed promptly to prevent potential failures.

When properly selected, lubricated, and maintained, engineering chains made from heat-resistant materials can reliably operate in high-temperature environments. It’s essential to consult with chain manufacturers or experts to determine the most suitable chain type and material for a specific high-temperature application.

How do engineering chains perform in dusty or dirty environments?

In dusty or dirty environments, engineering chains face unique challenges due to the presence of contaminants that can affect their performance and longevity. However, many engineering chains are designed to handle such harsh conditions, and their performance can be enhanced with proper maintenance and considerations.

1. Sealing and Protection: Some engineering chains come with specialized seals or protective coatings to prevent dust, dirt, and other contaminants from entering the chain’s internal components. These seals help maintain the integrity of the lubrication and reduce the risk of abrasive particles causing wear.

2. Lubrication: Proper and regular lubrication is essential for engineering chains operating in dusty environments. Lubrication helps reduce friction and wear, flushing out contaminants that may have entered the chain. It’s crucial to use lubricants suitable for dusty conditions to prevent excessive buildup of dirt and debris.

3. Cleaning and Maintenance: Regular cleaning and maintenance are crucial to keep the chain functioning optimally in dirty environments. Removing accumulated dirt and debris helps prevent abrasive wear and elongation of the chain.

4. Material Selection: Choosing the right materials for the chain is vital for dusty environments. Chains with corrosion-resistant coatings or made from stainless steel can better withstand the abrasive nature of dust and dirt.

5. Chain Design: The design of the engineering chain can also influence its performance in dusty environments. Some chains have self-cleaning features or specific geometry that helps shed dirt and debris during operation.

6. Regular Inspection: Regular visual inspection of the chain can help identify signs of wear and contamination early on, allowing for timely maintenance or replacement.

7. Environmental Considerations: Understanding the specific conditions of the dusty environment is essential for selecting the most suitable engineering chain. Factors such as temperature, humidity, and the type of contaminants present should be taken into account.

8. Ingress Protection (IP) Rating: In certain industries, such as food processing or pharmaceuticals, engineering chains with specific IP ratings may be required to ensure compliance with hygiene and cleanliness standards.

In conclusion, engineering chains can perform well in dusty or dirty environments if properly selected, installed, and maintained. Regular cleaning, lubrication, and inspection are essential to ensure optimal performance and extend the chain’s service life in such challenging conditions.

Can engineering chains be used in corrosive or harsh environments?

Yes, engineering chains can be designed and manufactured to withstand corrosive or harsh environments. When operating in such conditions, it is crucial to select the appropriate materials and coatings for the chain to ensure its durability and performance. Here are some considerations for using engineering chains in corrosive or harsh environments:

1. Material Selection: Choose materials that have high corrosion resistance, such as stainless steel or nickel-plated chains. These materials can withstand exposure to moisture, chemicals, and other corrosive agents.

2. Coatings and Surface Treatments: Applying specialized coatings or surface treatments to the chain can further enhance its corrosion resistance. Common coatings include zinc plating, chromate conversion coating, and polymer coatings.

3. Sealed Joints: Opt for engineering chains with sealed joints or special seals to protect the internal components from contaminants and moisture, reducing the risk of corrosion.

4. Environmental Ratings: Some engineering chains may come with specific environmental ratings that indicate their suitability for certain conditions. Check these ratings to ensure the chain is appropriate for the intended environment.

5. Regular Maintenance: Even with corrosion-resistant materials and coatings, regular maintenance is essential. Keep the chain clean, lubricated, and free from debris to prevent corrosion and premature wear.

6. Compatibility with Other Components: Ensure that all components in the chain system, such as sprockets and bearings, are also suitable for use in corrosive environments.

7. Temperature Considerations: Take into account the operating temperature range of the environment. Some materials may perform differently at extreme temperatures, affecting the chain’s overall performance.

8. Chemical Exposure: If the chain will be exposed to specific chemicals or substances, verify that the chosen materials and coatings are resistant to those chemicals.

By carefully selecting the right materials, coatings, and design features, engineering chains can effectively handle corrosive or harsh environments, maintaining their functionality and longevity in challenging industrial applications.

editor by CX 2024-04-10

China manufacturer 09063-A42 (A) Steel Engineering Class Conveyor Chain for Sugar Mill Roller Chain for Sugar Industry Chains

Product Description

Product Description

KASIN intermediate carrier chains operate in the most corrosive conditions brought about by continous operation in raw sugar juice.As a consquence chains employ corrosion resistant materials . The swivel attachments allows for self allignment of the strands during operation compensating for anymismatch.

Related Products

About Us

Kasin group was established in 1989, and its first product is casting carrier trolley for power & free conveyor system. In 1995, CHINAMFG purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to power & free line market in china. With this acquisition, CHINAMFG positioned itself as 1 of major parts suppliers of monorail and power & free conveyor system in china.

In 2

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy |

|---|---|

| Structure: | Roller Chain |

| Surface Treatment: | Polishing |

| Feature: | Fire Resistant, Oil Resistant, Heat Resistant |

| Pitch: | 152.40mm |

| Roller Dia: | 76.20mm |

| Samples: |

US$ 100/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can engineering chains be used in agricultural machinery and equipment?

Yes, engineering chains are commonly used in various agricultural machinery and equipment applications. Their robust design and ability to handle heavy loads make them well-suited for the demanding and often harsh conditions in the agricultural industry. Here are some examples of how engineering chains are used in agriculture:

- Combine Harvesters: Engineering chains are utilized in combine harvesters to drive components like the cutter head, reel, and auger. These chains are essential for efficient harvesting and grain collection.

- Tractors: In tractors, engineering chains are employed in power take-off (PTO) systems to transfer power from the engine to different agricultural implements, such as plows, mowers, and tillers.

- Balers: Engineering chains are used in balers to compress and bind crops into bales, facilitating easy storage and transport.

- Seeders and Planters: These machines use engineering chains to distribute seeds or plants evenly in the field, ensuring proper crop spacing and optimal growth.

- Grain Handling Equipment: Engineering chains are integral in grain handling equipment, including bucket elevators, grain conveyors, and grain elevators, facilitating the efficient movement and storage of harvested crops.

The agricultural environment can be challenging, with factors such as dust, debris, and varying weather conditions. Engineering chains used in agricultural machinery are often designed with additional protection against contaminants and corrosion to ensure reliable performance over extended periods.

When selecting engineering chains for agricultural applications, it’s essential to consider factors like load capacity, environmental conditions, maintenance requirements, and the specific needs of each machine. Regular inspection and proper lubrication are crucial to maintain the chains’ performance and extend their service life in agricultural machinery.

Can engineering chains be used for power transmission in conveyor systems?

Yes, engineering chains are commonly used for power transmission in conveyor systems. Conveyor systems are widely employed in various industries for material handling, and they require reliable and efficient power transmission methods to move heavy loads over long distances. Engineering chains are well-suited for these applications due to their robust construction, high load-carrying capacity, and versatility.

Conveyor systems often consist of a series of sprockets and a continuous loop of engineering chain that runs over these sprockets. The chain is driven by a motorized sprocket, and as it moves, it carries the conveyed material along the conveyor’s length. The design of engineering chains ensures smooth engagement with the sprockets, enabling efficient power transmission and precise material handling.

Depending on the specific requirements of the conveyor system, various types of engineering chains can be used. For instance, for applications where cleanliness is crucial, stainless steel chains with self-lubricating properties may be employed. In environments with high corrosion potential, corrosion-resistant coatings on chain components can extend the chain’s lifespan.

Furthermore, engineering chains can be customized to fit different conveyor configurations, allowing for the design of complex conveyor systems that suit specific production processes or spatial limitations.

In summary, engineering chains are an excellent choice for power transmission in conveyor systems due to their durability, load capacity, and adaptability. They ensure smooth and reliable operation, making them indispensable in material handling and conveyor applications across various industries.

How does an engineering chain differ from a standard roller chain?

Engineering chains and standard roller chains share similarities in terms of their basic design, consisting of interconnected links that engage with sprockets for power transmission. However, there are key differences between the two types of chains:

- Application: Standard roller chains, also known as transmission chains, are primarily used for power transmission in industrial applications. They are commonly found in machinery, automotive, and other power transmission systems. On the other hand, engineering chains have a broader range of applications and are specifically designed for various industrial uses beyond pure power transmission.

- Design and Construction: Engineering chains are available in different configurations and materials to meet specific industrial needs. They come in various types like drag chains, apron chains, leaf chains, and more, each tailored for a particular application, such as material handling, lifting, or conveying. Standard roller chains have a more standardized design with cylindrical rollers, providing smooth motion in power transmission applications.

- Attachments: Engineering chains often feature attachments or extended pins that allow for the connection of specialized components or accessories. These attachments can be used for carrying loads, attaching products, or facilitating specific tasks in industrial processes. Standard roller chains, on the other hand, typically do not come with attachments.

- Load Capacity: Engineering chains are designed to handle a wide range of loads, including heavy loads, abrasive materials, and harsh environmental conditions. They are built to withstand the demands of rugged industrial settings. Standard roller chains are suitable for general power transmission applications and may not be as robust as engineering chains in challenging environments.

- Specialty Chains: Engineering chains include various specialty chains that cater to specific industries and applications, such as mining, agriculture, escalators, and more. Standard roller chains do not have the same diversity of specialized variants.

In summary, engineering chains are more versatile and adaptable, tailored to a broader range of industrial applications beyond power transmission. They offer a wider variety of designs, materials, and attachments to suit specific needs, making them suitable for demanding and specialized tasks in various industries.

editor by CX 2024-04-03

China manufacturer V Style Industral Heavy Duty Transmission Stainless Steel Conveyor Roller Engineering Chain for Paper Roll Mill Transmission

Product Description

V Style Industral Heavy Duty Transmission Stainless Steel Conveyor Roller Engineering Chain for Paper Roll Mill Transmission

—This series of conveyor chain is frequently utilized in papermaking industry for paper roll conveying applications.

Its top plates are welded CHINAMFG the chain. In order to ensure welding quality and a flat surface created by the top plates, we adopt multi-station automatic welding machine to perform synchronous welding to multiple welding spots. Thus, the deformation caused by regional welding is minimized. Meanwhile, the top plates are cold drawn so that smooth finish and surface evenness are guaranteed.

—Our paper roll conveyor chain comes with extended service life due to the following designs. Firstly, it is designed with additional SF1 shaft sleeves between the pin and the bushing. Secondly, at the both ends of pins, there are specialized bearings with arc shaped outer ring.

| Item Name | Standard transmission Roller Chains | Model | Series A, Series B |

| Row | Simplex/Duplex/Triplex | Application | Machinery Parts |

| Surface Treatment | Self-color/sand-blasted/shot-peening | Certification | ISO, ANSI, DIN, BS |

| Packing | Packaged in boxes and wooden cases, or packaged in reels and then on pallets. | Port | Any sea port or airport in China |

Related products

| Usage: | Transmission Chain, Drag Chain, Conveyor Chain, Dedicated Special Chain |

|---|---|

| Material: | Stainless steel |

| Surface Treatment: | Oil Blooming |

| Feature: | Oil Resistant |

| Chain Size: | 1/2"*3/32" |

| Structure: | Roller Chain |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

What are the limitations of using engineering chains in certain applications?

While engineering chains are versatile and widely used in various industries, they do have some limitations that should be considered when selecting them for specific applications:

- Speed Limitations: Engineering chains have a maximum recommended speed limit. High-speed applications may require specialized high-speed chains that are designed to reduce vibration and noise and maintain reliable performance at elevated speeds.

- Temperature Sensitivity: Extreme temperatures can affect the performance of engineering chains. In high-temperature environments, chains may experience accelerated wear and reduced strength. Similarly, in cryogenic conditions, the chain’s materials may become brittle and prone to breakage.

- Chemical Exposure: Exposure to corrosive chemicals or harsh environments can lead to chain degradation. Engineering chains used in such conditions should be made from materials that offer corrosion resistance or be appropriately coated to withstand chemical exposure.

- Shock Loads: While engineering chains can handle moderate shock loads and impact forces, excessive or sudden shock loads can cause chain failure. In applications with significant shock loads, additional measures such as shock-absorbing devices may be required.

- Maintenance Requirements: Engineering chains require regular maintenance, including proper lubrication and periodic inspection for wear and damage. Failure to maintain the chains can result in premature wear and unexpected failures.

- Alignment: Engineering chains may not perform optimally in applications with misaligned sprockets. Proper alignment is essential to ensure smooth operation and prevent excessive wear.

- Environmental Contaminants: Dust, dirt, and debris in certain environments, such as construction sites or agricultural fields, can accumulate on the chain and sprockets, leading to accelerated wear and reduced chain life.

- Load Capacity: While engineering chains have excellent load-carrying capabilities, applications with extremely high loads may require customized or heavy-duty chains to meet the specific requirements.

Understanding the limitations of engineering chains allows engineers and designers to make informed decisions when selecting the most suitable chain type for their applications. By considering factors like speed, temperature, chemical exposure, shock loads, and maintenance requirements, one can ensure the reliable and efficient performance of engineering chains in various industrial settings.

How do engineering chains handle side loads and lateral forces?

Engineering chains are designed to handle side loads and lateral forces effectively, making them suitable for applications where such forces may be present. The ability of engineering chains to handle side loads and lateral forces is primarily influenced by their construction and material properties.

Key factors contributing to the handling of side loads and lateral forces by engineering chains include:

- Chain Design: Engineering chains are often constructed with solid bushings and rollers that provide smooth articulation between the chain links. This design minimizes friction and wear, allowing the chain to better accommodate lateral movements.

- Material Selection: High-quality engineering chains are typically made from durable materials, such as alloy steel, that offer excellent tensile strength and resistance to fatigue. These material properties enable the chain to withstand lateral forces without deformation or failure.

- Clearances: The clearances between the chain components and the sprocket teeth are carefully engineered to ensure that the chain can flex and adjust to lateral forces without jamming or binding. Proper clearances also help reduce wear and noise during operation.

- Guidance Systems: In certain applications, additional guidance systems may be used to support the chain and maintain its alignment, especially when dealing with significant side loads. These guidance systems can include wear strips, guide rails, or other forms of lateral support.

It’s important to note that while engineering chains can handle some degree of side loads and lateral forces, excessive or prolonged lateral forces can lead to premature wear and reduced chain life. Therefore, it is crucial to select the appropriate chain size and design for the specific application and operating conditions to ensure optimal performance and longevity.

Regular maintenance, including proper lubrication and periodic inspection, is also essential to monitor chain wear and detect any signs of damage that may result from side loads or other external forces. By following proper maintenance practices, the engineering chain’s ability to handle side loads and lateral forces can be maximized, ensuring reliable and efficient power transmission in various industrial applications.

What are the advantages of using an engineering chain in industrial applications?

Engineering chains offer several advantages that make them highly suitable for a wide range of industrial applications:

- Robust and Durable: Engineering chains are built to withstand heavy loads, harsh environmental conditions, and abrasive materials commonly found in industrial settings. Their robust construction ensures long-lasting performance and reduces the frequency of replacements, contributing to cost-effectiveness.

- Versatility: With various types and configurations available, engineering chains are highly versatile. They can be adapted to a wide array of applications, such as material handling, conveyor systems, bucket elevators, and more. Different attachments and accessories further enhance their adaptability for specific tasks.

- Specialized Variants: The market offers a diverse selection of engineering chains with specialty variants designed for specific industries. Whether it’s mining, agriculture, automotive, or food processing, there is likely an engineering chain optimized for the unique demands of each application.

- High Load Capacity: Engineering chains are capable of handling heavy loads, making them suitable for heavy machinery, lifting equipment, and other industrial applications requiring substantial power transmission capabilities.

- Efficient Power Transmission: The design of engineering chains ensures smooth and efficient power transmission, reducing energy losses and improving overall system performance.

- Attachments and Accessories: Many engineering chains come with pre-installed or customizable attachments that enable them to perform specialized tasks. These attachments can include slats, buckets, rollers, and other components, enhancing their ability to carry, grip, or convey materials as needed.

- Reliable Performance: Due to their robust design and precise engineering, these chains provide reliable and consistent performance even under challenging conditions, contributing to increased productivity and reduced downtime.

- Wide Range of Materials: Engineering chains can be manufactured from various materials, including carbon steel, stainless steel, and plastic, allowing for compatibility with different operating environments and industries.

- Cost-Effective Solutions: Despite their higher initial cost compared to standard roller chains, engineering chains often prove to be cost-effective in the long run due to their extended service life and reduced maintenance needs.

In summary, engineering chains offer durability, versatility, and specialized features that make them an excellent choice for industrial applications where reliable and efficient power transmission is essential. Their ability to handle heavy loads, varied environments, and specific tasks sets them apart as a valuable component in numerous industrial processes.

editor by CX 2023-12-08

China factory Ss1114 -a Steel Engineering Class Conveyor Chain for Sugar Mill Roller Chain for Sugar Industry Chains

Product Description

Product Description

KASIN intermediate carrier chains operate in the most corrosive conditions brought about by continous operation in raw sugar juice.As a consquence chains employ corrosion resistant materials . The swivel attachments allows for self allignment of the strands during operation compensating for anymismatch.

Related Products

About Us

Kasin group was established in 1989, and its first product is casting carrier trolley for power & free conveyor system. In 1995, CHINAMFG purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to power & free line market in china. With this acquisition, CHINAMFG positioned itself as 1 of major parts suppliers of monorail and power & free conveyor system in china.

In 2

| Material: | Alloy |

|---|---|

| Structure: | Roller Chain |

| Surface Treatment: | Polishing |

| Feature: | Fire Resistant, Oil Resistant, Heat Resistant |

| Link Plate Height: | 38.50 mm |

| Pin Length: | 81.70mm |

| Samples: |

US$ 100/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do engineering chains compare to other types of chains in terms of efficiency?

Engineering chains are known for their high efficiency in power transmission compared to some other types of chains. Their efficiency can be attributed to several factors:

- Minimal Friction: Engineering chains are designed with precision rollers and bushings, which reduces friction between the chain’s components. This results in less energy loss during power transmission.

- High-Quality Materials: These chains are typically made from high-quality materials, such as alloy steel, which ensures durability and minimal elongation under heavy loads. This material choice helps maintain efficiency over extended periods of use.

- Precise Manufacturing: Engineering chains are manufactured with tight tolerances and precise engineering, ensuring consistent performance and smooth operation. This precision minimizes energy losses due to chain misalignment or uneven loading.

- Optimized Design: The design of engineering chains takes into account the specific requirements of power transmission, making them well-suited for their intended applications. This optimized design contributes to their overall efficiency.

- Proper Lubrication: Regular and proper lubrication of engineering chains is essential to maintain their efficiency. Adequate lubrication reduces friction and wear, optimizing power transfer efficiency.

Compared to some other types of chains, such as standard roller chains, engineering chains may offer higher efficiency due to their advanced design and manufacturing processes. However, the choice of chain type depends on the specific application requirements, load conditions, operating environment, and other factors.

In certain applications, other power transmission methods like belts or gears might be preferred over chains, based on factors such as noise level, space constraints, and maintenance considerations. Each power transmission method has its advantages and limitations, and selecting the most suitable option requires careful consideration of the application’s needs.

What are the environmental considerations when using engineering chains?

When using engineering chains in various applications, there are several environmental considerations to keep in mind to ensure optimal performance, longevity, and safety. These considerations include:

1. Temperature: Extreme temperatures, whether high or low, can affect the performance and lifespan of engineering chains. Proper lubrication and material selection are essential to ensure the chain can withstand the temperature conditions in the operating environment.

2. Corrosive Environments: In corrosive environments, such as those with exposure to chemicals, saltwater, or other corrosive substances, it’s crucial to choose engineering chains made from corrosion-resistant materials, such as stainless steel or coatings that provide protection against corrosion.

3. Dust and Contaminants: Dust, dirt, and other contaminants can accumulate on the chain, leading to increased wear and reduced efficiency. Regular cleaning and proper chain guarding can help minimize the impact of these environmental factors.

4. Moisture and Water Exposure: For applications exposed to moisture or water, selecting chains with appropriate sealing or corrosion-resistant coatings is important to prevent rust and maintain performance.

5. UV Exposure: Outdoor applications exposed to direct sunlight can be subject to UV degradation. Using engineering chains with UV-resistant materials or protective coatings can help mitigate the effects of UV exposure.

6. Noise and Vibration: Certain environments may have strict noise regulations. In such cases, using chain guides, dampers, or other noise-reducing features can help lower the noise and vibration levels produced by the chain.

7. Load Variation: Environmental conditions may lead to variations in the load on the chain. Understanding and accommodating load variations is crucial for ensuring the chain’s reliability and preventing premature failure.

8. Compliance with Regulations: Some industries have specific environmental regulations that must be adhered to. It’s essential to select engineering chains that comply with these regulations to maintain a safe and environmentally friendly operation.

9. Maintenance and Lubrication: Proper and regular maintenance, including lubrication, is critical to ensure the chain’s smooth operation and extend its service life in any environment.

Considering these environmental factors will help in selecting the right engineering chain for a particular application, ensuring optimal performance, and reducing the risk of chain failure due to environmental conditions.

Can engineering chains be used in corrosive or harsh environments?

Yes, engineering chains can be designed and manufactured to withstand corrosive or harsh environments. When operating in such conditions, it is crucial to select the appropriate materials and coatings for the chain to ensure its durability and performance. Here are some considerations for using engineering chains in corrosive or harsh environments:

1. Material Selection: Choose materials that have high corrosion resistance, such as stainless steel or nickel-plated chains. These materials can withstand exposure to moisture, chemicals, and other corrosive agents.

2. Coatings and Surface Treatments: Applying specialized coatings or surface treatments to the chain can further enhance its corrosion resistance. Common coatings include zinc plating, chromate conversion coating, and polymer coatings.

3. Sealed Joints: Opt for engineering chains with sealed joints or special seals to protect the internal components from contaminants and moisture, reducing the risk of corrosion.

4. Environmental Ratings: Some engineering chains may come with specific environmental ratings that indicate their suitability for certain conditions. Check these ratings to ensure the chain is appropriate for the intended environment.

5. Regular Maintenance: Even with corrosion-resistant materials and coatings, regular maintenance is essential. Keep the chain clean, lubricated, and free from debris to prevent corrosion and premature wear.

6. Compatibility with Other Components: Ensure that all components in the chain system, such as sprockets and bearings, are also suitable for use in corrosive environments.

7. Temperature Considerations: Take into account the operating temperature range of the environment. Some materials may perform differently at extreme temperatures, affecting the chain’s overall performance.

8. Chemical Exposure: If the chain will be exposed to specific chemicals or substances, verify that the chosen materials and coatings are resistant to those chemicals.

By carefully selecting the right materials, coatings, and design features, engineering chains can effectively handle corrosive or harsh environments, maintaining their functionality and longevity in challenging industrial applications.

editor by CX 2023-10-21

China wholesaler Ss1124-A42 (B) Steel Engineering Class Conveyor Chain for Sugar Mill Roller Chain for Sugar Industry Chains

Product Description

Product Description

KASIN intermediate carrier chains operate in the most corrosive conditions brought about by continous operation in raw sugar juice.As a consquence chains employ corrosion resistant materials . The swivel attachments allows for self allignment of the strands during operation compensating for anymismatch.

Related Products

About Us

Kasin group was established in 1989, and its first product is casting carrier trolley for power & free conveyor system. In 1995, CHINAMFG purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to power & free line market in china. With this acquisition, CHINAMFG positioned itself as 1 of major parts suppliers of monorail and power & free conveyor system in china.

In 2

| Material: | Alloy |

|---|---|

| Structure: | Roller Chain |

| Surface Treatment: | Polishing |

| Feature: | Fire Resistant, Oil Resistant, Heat Resistant |

| Link Plate Height: | 38.10 mm |

| Pin Length: | 80.60mm |

| Samples: |

US$ 100/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the signs of wear and when should an engineering chain be replaced?

Identifying signs of wear in an engineering chain is crucial for maintaining the system’s reliability and preventing unexpected failures. Here are some common signs of wear in an engineering chain that indicate it may need replacement:

1. Elongation: Over time, chains can elongate due to wear on the pins and bushings. Measure the chain’s pitch (center-to-center distance between pins) and compare it to the original pitch. If the elongation exceeds the manufacturer’s recommended limit, it’s time to replace the chain.

2. Chain Stretch: Chain stretch occurs when the chain has excessive play or slack when engaged with the sprockets. This can result from elongation and may lead to a loss of accuracy in the system’s operation.

3. Increased Noise: Excessive wear can cause the chain to produce more noise during operation. If you notice a significant increase in chain noise, it may indicate wear or inadequate lubrication.

4. Chain Damage: Inspect the chain for signs of damage, such as bent or broken links, cracked plates, or damaged rollers. Damaged components compromise the chain’s integrity and can lead to failure.

5. Rust and Corrosion: Chains used in corrosive environments may show signs of rust and corrosion. Corroded components can weaken the chain and reduce its load-carrying capacity.

6. Frequent Maintenance and Repairs: If you find yourself frequently performing maintenance and repairs on the chain, it may be an indication that it is nearing the end of its service life.

7. Chain Misalignment: Excessive wear can cause the chain to misalign with the sprockets, leading to uneven wear patterns on the chain components.

8. Loss of Tension: In applications where tension is crucial for proper chain engagement, a loss of tension could indicate wear or elongation.

9. Reduced Performance: If the system’s performance, such as speed or accuracy, is noticeably reduced, it could be due to chain wear affecting the overall functionality.

10. Maintenance Records: Keep detailed records of the chain’s maintenance and service life. Regularly inspect the chain and refer to maintenance records to determine if it has reached its recommended replacement interval.

When you observe any of these signs of wear, it’s important to replace the engineering chain promptly. Continuing to use a worn or damaged chain can lead to unexpected failures, production downtime, and potential damage to other system components. Regular inspections, proper lubrication, and timely replacement will ensure the reliability and longevity of the engineering chain in various industrial applications.

Can engineering chains be used for power transmission in conveyor systems?

Yes, engineering chains are commonly used for power transmission in conveyor systems. Conveyor systems are widely employed in various industries for material handling, and they require reliable and efficient power transmission methods to move heavy loads over long distances. Engineering chains are well-suited for these applications due to their robust construction, high load-carrying capacity, and versatility.

Conveyor systems often consist of a series of sprockets and a continuous loop of engineering chain that runs over these sprockets. The chain is driven by a motorized sprocket, and as it moves, it carries the conveyed material along the conveyor’s length. The design of engineering chains ensures smooth engagement with the sprockets, enabling efficient power transmission and precise material handling.

Depending on the specific requirements of the conveyor system, various types of engineering chains can be used. For instance, for applications where cleanliness is crucial, stainless steel chains with self-lubricating properties may be employed. In environments with high corrosion potential, corrosion-resistant coatings on chain components can extend the chain’s lifespan.

Furthermore, engineering chains can be customized to fit different conveyor configurations, allowing for the design of complex conveyor systems that suit specific production processes or spatial limitations.

In summary, engineering chains are an excellent choice for power transmission in conveyor systems due to their durability, load capacity, and adaptability. They ensure smooth and reliable operation, making them indispensable in material handling and conveyor applications across various industries.

Can engineering chains handle heavy loads and high torque requirements?

Yes, engineering chains are designed to handle heavy loads and high torque requirements, making them well-suited for various industrial applications that demand robust power transmission capabilities. The construction and materials used in engineering chains ensure their ability to withstand the stresses and forces associated with heavy loads and high torque.

Engineering chains are commonly used in heavy machinery, mining equipment, construction machinery, and other applications where substantial power transmission is necessary. Their sturdy design and precise engineering allow them to efficiently transmit power and handle the forces generated during operation.

The load capacity and torque-handling capabilities of engineering chains can vary depending on their design, size, and material. Manufacturers provide technical specifications and load ratings for different engineering chain types, enabling users to select the appropriate chain based on their specific application requirements.

In summary, engineering chains are well-equipped to handle heavy loads and high torque requirements, making them reliable and effective components in industrial systems that demand strength, durability, and efficient power transmission.

editor by CX 2023-10-20

China Professional Ss1125 -B Steel Engineering Class Conveyor Chain for Sugar Mill Roller Chain for Sugar Industry Chains

Product Description

Product Description

KASIN intermediate carrier chains operate in the most corrosive conditions brought about by continous operation in raw sugar juice.As a consquence chains employ corrosion resistant materials . The swivel attachments allows for self allignment of the strands during operation compensating for anymismatch.

Related Products

About Us

Kasin group was established in 1989, and its first product is casting carrier trolley for power & free conveyor system. In 1995, CHINAMFG purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to power & free line market in china. With this acquisition, CHINAMFG positioned itself as 1 of major parts suppliers of monorail and power & free conveyor system in china.

In 2

| Material: | Alloy |

|---|---|

| Structure: | Roller Chain |

| Surface Treatment: | Polishing |

| Feature: | Fire Resistant, Oil Resistant, Heat Resistant |

| Link Plate Height: | 44.50 mm |

| Pin Length: | 83.00mm |

| Samples: |

US$ 100/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the limitations of using engineering chains in certain applications?

While engineering chains are versatile and widely used in various industries, they do have some limitations that should be considered when selecting them for specific applications:

- Speed Limitations: Engineering chains have a maximum recommended speed limit. High-speed applications may require specialized high-speed chains that are designed to reduce vibration and noise and maintain reliable performance at elevated speeds.

- Temperature Sensitivity: Extreme temperatures can affect the performance of engineering chains. In high-temperature environments, chains may experience accelerated wear and reduced strength. Similarly, in cryogenic conditions, the chain’s materials may become brittle and prone to breakage.

- Chemical Exposure: Exposure to corrosive chemicals or harsh environments can lead to chain degradation. Engineering chains used in such conditions should be made from materials that offer corrosion resistance or be appropriately coated to withstand chemical exposure.

- Shock Loads: While engineering chains can handle moderate shock loads and impact forces, excessive or sudden shock loads can cause chain failure. In applications with significant shock loads, additional measures such as shock-absorbing devices may be required.

- Maintenance Requirements: Engineering chains require regular maintenance, including proper lubrication and periodic inspection for wear and damage. Failure to maintain the chains can result in premature wear and unexpected failures.

- Alignment: Engineering chains may not perform optimally in applications with misaligned sprockets. Proper alignment is essential to ensure smooth operation and prevent excessive wear.

- Environmental Contaminants: Dust, dirt, and debris in certain environments, such as construction sites or agricultural fields, can accumulate on the chain and sprockets, leading to accelerated wear and reduced chain life.

- Load Capacity: While engineering chains have excellent load-carrying capabilities, applications with extremely high loads may require customized or heavy-duty chains to meet the specific requirements.

Understanding the limitations of engineering chains allows engineers and designers to make informed decisions when selecting the most suitable chain type for their applications. By considering factors like speed, temperature, chemical exposure, shock loads, and maintenance requirements, one can ensure the reliable and efficient performance of engineering chains in various industrial settings.

How do engineering chains perform in dusty or dirty environments?

In dusty or dirty environments, engineering chains face unique challenges due to the presence of contaminants that can affect their performance and longevity. However, many engineering chains are designed to handle such harsh conditions, and their performance can be enhanced with proper maintenance and considerations.

1. Sealing and Protection: Some engineering chains come with specialized seals or protective coatings to prevent dust, dirt, and other contaminants from entering the chain’s internal components. These seals help maintain the integrity of the lubrication and reduce the risk of abrasive particles causing wear.

2. Lubrication: Proper and regular lubrication is essential for engineering chains operating in dusty environments. Lubrication helps reduce friction and wear, flushing out contaminants that may have entered the chain. It’s crucial to use lubricants suitable for dusty conditions to prevent excessive buildup of dirt and debris.

3. Cleaning and Maintenance: Regular cleaning and maintenance are crucial to keep the chain functioning optimally in dirty environments. Removing accumulated dirt and debris helps prevent abrasive wear and elongation of the chain.

4. Material Selection: Choosing the right materials for the chain is vital for dusty environments. Chains with corrosion-resistant coatings or made from stainless steel can better withstand the abrasive nature of dust and dirt.

5. Chain Design: The design of the engineering chain can also influence its performance in dusty environments. Some chains have self-cleaning features or specific geometry that helps shed dirt and debris during operation.

6. Regular Inspection: Regular visual inspection of the chain can help identify signs of wear and contamination early on, allowing for timely maintenance or replacement.

7. Environmental Considerations: Understanding the specific conditions of the dusty environment is essential for selecting the most suitable engineering chain. Factors such as temperature, humidity, and the type of contaminants present should be taken into account.

8. Ingress Protection (IP) Rating: In certain industries, such as food processing or pharmaceuticals, engineering chains with specific IP ratings may be required to ensure compliance with hygiene and cleanliness standards.

In conclusion, engineering chains can perform well in dusty or dirty environments if properly selected, installed, and maintained. Regular cleaning, lubrication, and inspection are essential to ensure optimal performance and extend the chain’s service life in such challenging conditions.

Can engineering chains be used in high-speed applications?

Yes, engineering chains can be used in high-speed applications, but their suitability depends on various factors. While some engineering chains are designed to handle high-speed operation, others may not be suitable for such applications. Here are some considerations:

1. Chain Type: Different types of engineering chains have varying capabilities when it comes to high-speed operation. For example, roller chains are commonly used in industrial applications and can handle moderate to high speeds efficiently. On the other hand, conveyor chains or specialty chains may have limitations on speed due to their design and intended use.

2. Manufacturer Specifications: Check the manufacturer’s specifications and recommendations for the engineering chain you plan to use. Manufacturers often provide maximum allowable speeds for their chains based on factors such as chain size, material, and construction.

3. Lubrication and Maintenance: Proper lubrication and maintenance are critical for high-speed applications. Adequate lubrication reduces friction and wear, allowing the chain to operate smoothly at higher speeds. Regular maintenance ensures that the chain remains in good condition and minimizes the risk of unexpected failures.

4. Load and Tension: High-speed applications can place additional loads and tension on the engineering chain. It is essential to ensure that the chain can handle the increased loads and tension without stretching excessively or experiencing premature wear.

5. Environmental Conditions: Consider the environmental factors that may affect the chain’s performance at high speeds. Temperature, humidity, and the presence of contaminants can impact the chain’s wear and durability.

6. Safety Considerations: High-speed applications require careful consideration of safety measures. Ensure that all safety guidelines and regulations are followed to prevent accidents or injuries resulting from chain failure.

In summary, engineering chains can be used in high-speed applications, but it is essential to select the appropriate chain type and ensure proper maintenance and lubrication. Consulting with chain manufacturers or experts can help you determine the most suitable engineering chain for your specific high-speed application, ensuring safe and reliable operation.

editor by CX 2023-10-07

China Standard 09063-A42 (A) Steel Engineering Class Conveyor Chain for Sugar Mill Roller Chain for Sugar Industry Chains

Product Description

Product Description

KASIN intermediate carrier chains operate in the most corrosive conditions brought about by continous operation in raw sugar juice.As a consquence chains employ corrosion resistant materials . The swivel attachments allows for self allignment of the strands during operation compensating for anymismatch.

Related Products

About Us

Kasin group was established in 1989, and its first product is casting carrier trolley for power & free conveyor system. In 1995, CZPT purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to power & free line market in china. With this acquisition, CZPT positioned itself as 1 of major parts suppliers of monorail and power & free conveyor system in china.

In 2

| Material: | Alloy |

|---|---|

| Structure: | Roller Chain |

| Surface Treatment: | Polishing |

| Feature: | Fire Resistant, Oil Resistant, Heat Resistant |

| Link Plate Height: | 63.50mm |

| Pin Length: | 103.00mm |

| Samples: |

US$ 100/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can engineering chains be used in overhead or inverted applications?