Product Description

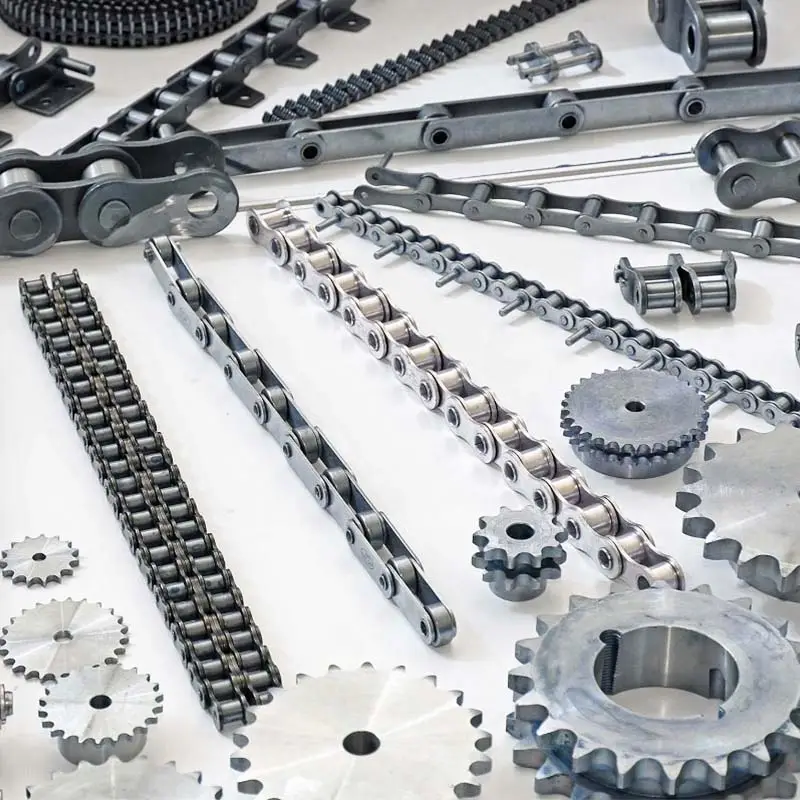

S Type Engineering High Precision Industrial Transmission Conveyor Roller Chain

Product Description

1. Material: Alloy steel & Stainless steel

2. Surface treatment: Shot peening / Zinc-plated / Nickel-plated / Dacromet-plated

3. Characteristic: Chain plate hole finally passed ball extrusion to ensure maximum fatigue resistance, parts of shot peening treatment makes the chain and the sleeve has a higher fatigue strength.

| Materials Available | 1. Stainless Steel: SS304, SS316, etc |

| 2. Alloy Steel: 45Mn, 42CrMo, etc | |

| 3. OEM according to your request | |

| Surface Treatment | Shot peening, Polishing, Oxygenation, Blackening, Zinc-plated, Nickel-plated, Anodized, etc. |

| Characteristic | Fire Resistant, Oil Resistant, Heat Resistant |

| Application | Agricultural machine |

| Design criterion | ISO DIN ANSI & Customer’s Drawing |

| Size | Customer’s Drawing & ISO standard |

| Package | Wooden Case / Container and pallet, or made-to-order |

| Certificate | ISO9001: 2008 |

| Advantage | First quality, best service, competitive price, fast delivery |

| Delivery Time | 20 days for samples. 45 days for official order. |

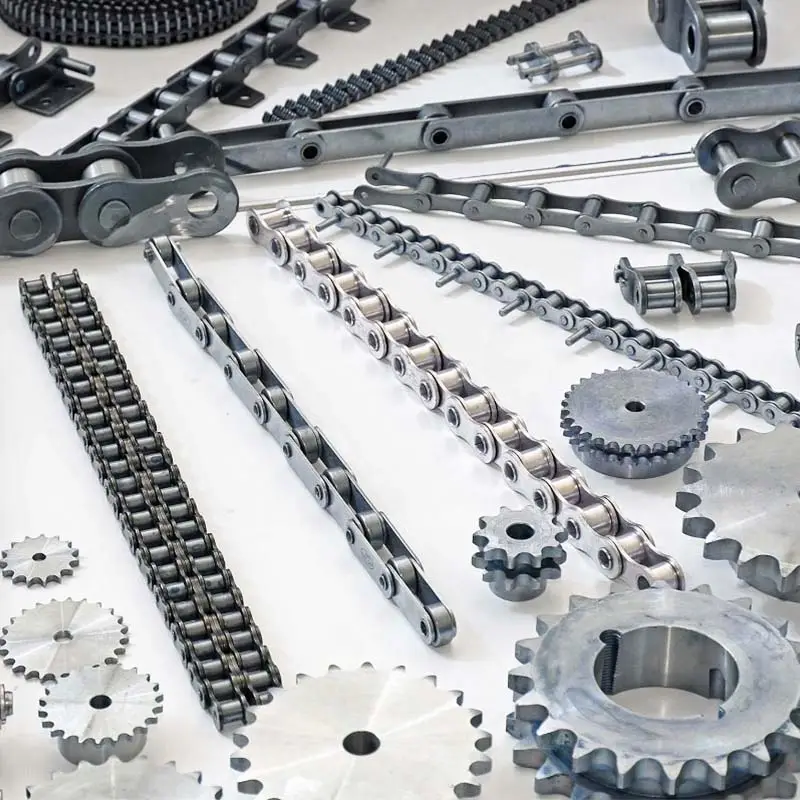

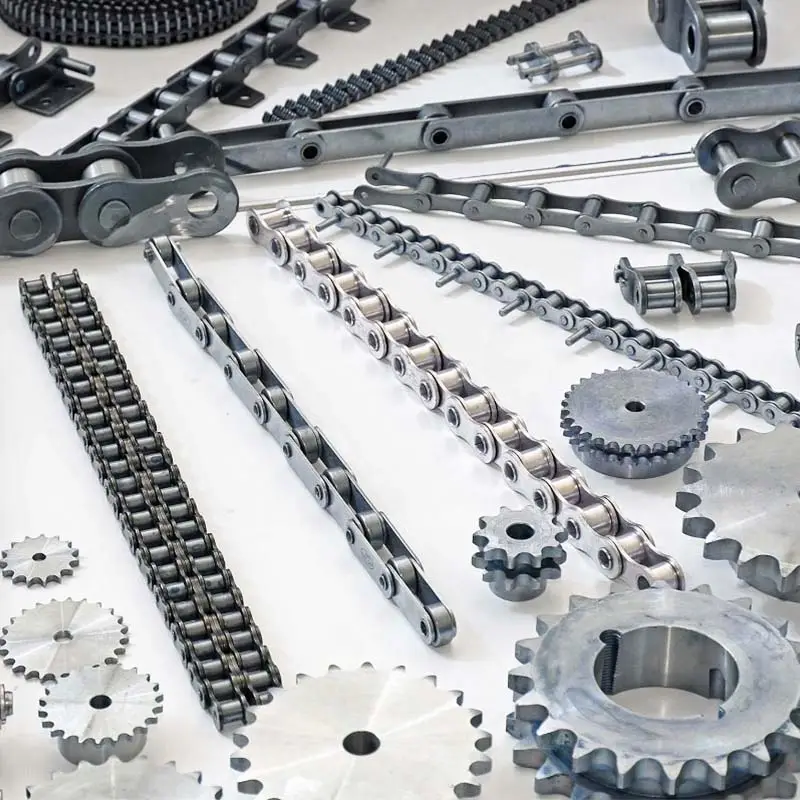

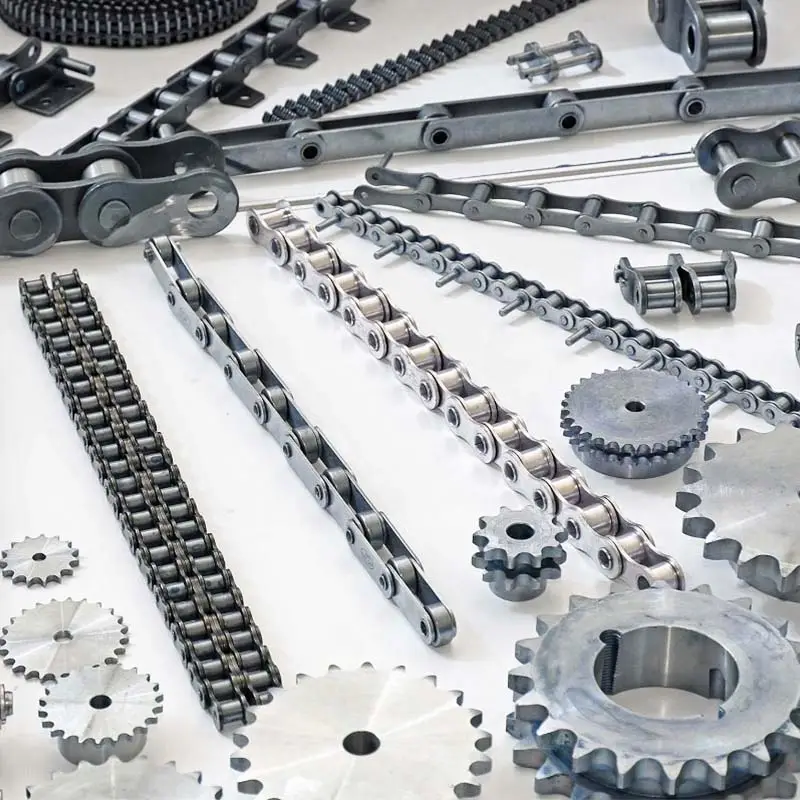

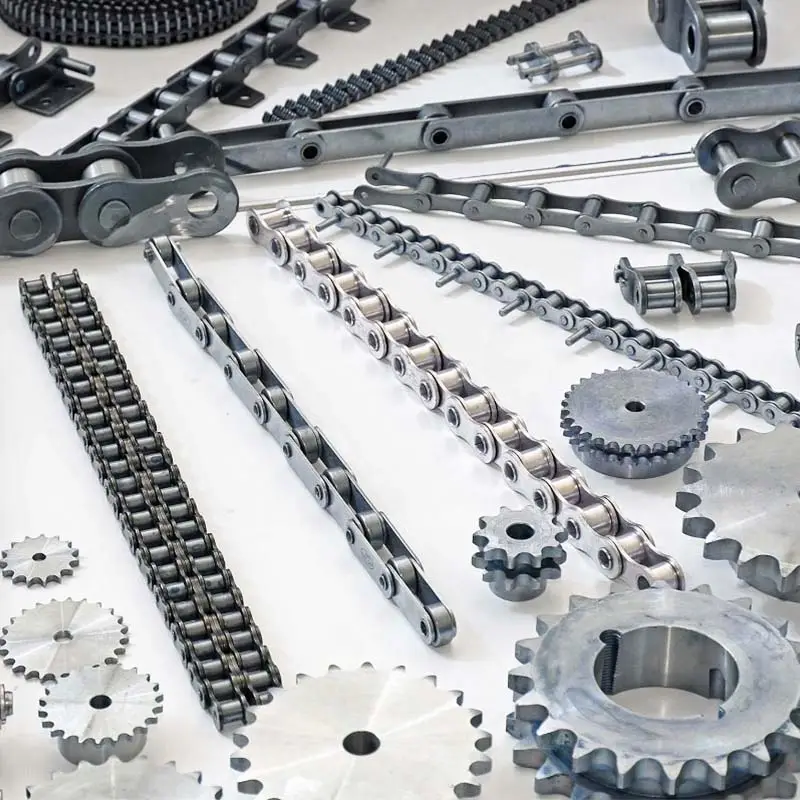

Detailed Photos

View more products,please click here…

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy/Carbon Steel |

|---|---|

| Sample: | for Free |

| Transport Package: | Plastic Bag+Carton Box+Plywood Case |

| Specification: | S55K1, S62A2K1 |

| Trademark: | made-to-order |

| Origin: | China |

| Samples: |

US$ 0/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the signs of wear and when should an engineering chain be replaced?

Identifying signs of wear in an engineering chain is crucial for maintaining the system’s reliability and preventing unexpected failures. Here are some common signs of wear in an engineering chain that indicate it may need replacement:

1. Elongation: Over time, chains can elongate due to wear on the pins and bushings. Measure the chain’s pitch (center-to-center distance between pins) and compare it to the original pitch. If the elongation exceeds the manufacturer’s recommended limit, it’s time to replace the chain.

2. Chain Stretch: Chain stretch occurs when the chain has excessive play or slack when engaged with the sprockets. This can result from elongation and may lead to a loss of accuracy in the system’s operation.

3. Increased Noise: Excessive wear can cause the chain to produce more noise during operation. If you notice a significant increase in chain noise, it may indicate wear or inadequate lubrication.

4. Chain Damage: Inspect the chain for signs of damage, such as bent or broken links, cracked plates, or damaged rollers. Damaged components compromise the chain’s integrity and can lead to failure.

5. Rust and Corrosion: Chains used in corrosive environments may show signs of rust and corrosion. Corroded components can weaken the chain and reduce its load-carrying capacity.

6. Frequent Maintenance and Repairs: If you find yourself frequently performing maintenance and repairs on the chain, it may be an indication that it is nearing the end of its service life.

7. Chain Misalignment: Excessive wear can cause the chain to misalign with the sprockets, leading to uneven wear patterns on the chain components.

8. Loss of Tension: In applications where tension is crucial for proper chain engagement, a loss of tension could indicate wear or elongation.

9. Reduced Performance: If the system’s performance, such as speed or accuracy, is noticeably reduced, it could be due to chain wear affecting the overall functionality.

10. Maintenance Records: Keep detailed records of the chain’s maintenance and service life. Regularly inspect the chain and refer to maintenance records to determine if it has reached its recommended replacement interval.

When you observe any of these signs of wear, it’s important to replace the engineering chain promptly. Continuing to use a worn or damaged chain can lead to unexpected failures, production downtime, and potential damage to other system components. Regular inspections, proper lubrication, and timely replacement will ensure the reliability and longevity of the engineering chain in various industrial applications.

How do engineering chains handle reverse motion or anti-reverse requirements?

Engineering chains are designed to handle reverse motion or anti-reverse requirements in certain applications. This capability is essential in situations where the load or the machinery needs to move back and forth. Here’s how engineering chains achieve this:

1. Tooth Shape: Many engineering chains, such as roller chains or silent chains, feature a specific tooth shape on the sprockets. The tooth profile is designed to engage the chain rollers or links in one direction, allowing smooth motion, while preventing engagement in the reverse direction, effectively acting as an anti-reverse mechanism.

2. One-Way Clutches: Some engineering chain applications may incorporate one-way clutches or overrunning clutches. These devices allow the chain and sprockets to engage and transmit power in one direction, while freewheeling or disengaging in the opposite direction, preventing reverse motion.

3. Ratcheting Mechanisms: In certain engineering chain systems, ratcheting mechanisms are employed to allow forward motion and prevent backward movement. These mechanisms consist of pawls and teeth that engage in one direction and disengage in the reverse direction, effectively providing an anti-reverse function.

4. Backstop Clutches: Backstop clutches are used to prevent reverse motion in specific engineering chain applications. These clutches allow the chain to engage and transmit power in one direction, while locking and preventing motion in the reverse direction.

5. Tensioning Devices: Proper tensioning of the engineering chain can also play a role in preventing reverse motion. Adequate tension helps keep the chain engaged with the sprockets in the desired direction, reducing the risk of slipping or backdriving.

6. Design and Orientation: Engineers can design the system in a way that naturally discourages reverse motion. For example, the layout of the chain path and the arrangement of sprockets can make it less likely for the chain to move in the opposite direction.

By using these methods and incorporating suitable components, engineering chains can effectively handle reverse motion or anti-reverse requirements, ensuring the safe and reliable operation of machinery in applications where back-and-forth motion is necessary.

Can engineering chains handle heavy loads and high torque requirements?

Yes, engineering chains are designed to handle heavy loads and high torque requirements, making them well-suited for various industrial applications that demand robust power transmission capabilities. The construction and materials used in engineering chains ensure their ability to withstand the stresses and forces associated with heavy loads and high torque.

Engineering chains are commonly used in heavy machinery, mining equipment, construction machinery, and other applications where substantial power transmission is necessary. Their sturdy design and precise engineering allow them to efficiently transmit power and handle the forces generated during operation.

The load capacity and torque-handling capabilities of engineering chains can vary depending on their design, size, and material. Manufacturers provide technical specifications and load ratings for different engineering chain types, enabling users to select the appropriate chain based on their specific application requirements.

In summary, engineering chains are well-equipped to handle heavy loads and high torque requirements, making them reliable and effective components in industrial systems that demand strength, durability, and efficient power transmission.

editor by CX 2024-04-29

China best Good Service Alloy Steel Material Standard Conveyor Engineering Industrial Agricultural Chain with Attachment

Product Description

Good Service Alloy Steel Material Standard Conveyor Engineering Industrial Agricultural Chain with Attachment

Product Description

1. Material: Alloy steel & Stainless steel

2. Surface treatment: Shot peening / Zinc-plated / Nickel-plated / Dacromet-plated

3. Characteristic: Chain plate hole finally passed ball extrusion to ensure maximum fatigue resistance, parts of shot peening treatment makes the chain and the sleeve has a higher fatigue strength.

| Materials Available | 1. Stainless Steel: SS304, SS316, etc |

| 2. Alloy Steel: 45Mn, 42CrMo, etc | |

| 3. OEM according to your request | |

| Surface Treatment | Shot peening, Polishing, Oxygenation, Blackening, Zinc-plated, Nickel-plated, Anodized, etc. |

| Characteristic | Fire Resistant, Oil Resistant, Heat Resistant |

| Application | Agricultural machine |

| Design criterion | ISO DIN ANSI & Customer’s Drawing |

| Size | Customer’s Drawing & ISO standard |

| Package | Wooden Case / Container and pallet, or made-to-order |

| Certificate | ISO9001: 2008 |

| Advantage | First quality, best service, competitive price, fast delivery |

| Delivery Time | 20 days for samples. 45 days for official order. |

Detailed Photos

View more products,please click here…

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy/Carbon Steel |

|---|---|

| Sample: | for Free |

| Transport Package: | Plastic Bag+Carton Box+Plywood Case |

| Specification: | S55K1, S62A2K1 |

| Trademark: | made-to-order |

| Origin: | China |

| Samples: |

US$ 0/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can engineering chains be used in agricultural machinery and equipment?

Yes, engineering chains are commonly used in various agricultural machinery and equipment applications. Their robust design and ability to handle heavy loads make them well-suited for the demanding and often harsh conditions in the agricultural industry. Here are some examples of how engineering chains are used in agriculture:

- Combine Harvesters: Engineering chains are utilized in combine harvesters to drive components like the cutter head, reel, and auger. These chains are essential for efficient harvesting and grain collection.

- Tractors: In tractors, engineering chains are employed in power take-off (PTO) systems to transfer power from the engine to different agricultural implements, such as plows, mowers, and tillers.

- Balers: Engineering chains are used in balers to compress and bind crops into bales, facilitating easy storage and transport.

- Seeders and Planters: These machines use engineering chains to distribute seeds or plants evenly in the field, ensuring proper crop spacing and optimal growth.

- Grain Handling Equipment: Engineering chains are integral in grain handling equipment, including bucket elevators, grain conveyors, and grain elevators, facilitating the efficient movement and storage of harvested crops.

The agricultural environment can be challenging, with factors such as dust, debris, and varying weather conditions. Engineering chains used in agricultural machinery are often designed with additional protection against contaminants and corrosion to ensure reliable performance over extended periods.

When selecting engineering chains for agricultural applications, it’s essential to consider factors like load capacity, environmental conditions, maintenance requirements, and the specific needs of each machine. Regular inspection and proper lubrication are crucial to maintain the chains’ performance and extend their service life in agricultural machinery.

Can engineering chains be used in food processing or packaging industries?

Yes, engineering chains can be used in food processing and packaging industries under certain conditions. However, several considerations must be taken into account to ensure the safe and hygienic use of engineering chains in such applications.

Key factors to consider when using engineering chains in the food industry include:

- Food-Grade Materials: Engineering chains intended for use in food processing and packaging must be made from food-grade materials that meet industry standards for cleanliness and hygiene. Stainless steel chains are commonly used in these applications due to their corrosion resistance and ease of cleaning.

- Design and Construction: The chain design should minimize crevices, pockets, or areas that can trap food particles or contaminants. Smooth surfaces and sealed joints are preferred to facilitate thorough cleaning and prevent bacterial growth.

- Temperature and Chemical Resistance: Engineering chains should be capable of withstanding the temperature ranges and cleaning agents used in food processing facilities without compromising their performance or integrity.

- Lubrication: If lubrication is required, food-grade lubricants must be used to avoid contamination of the food products or packaging materials.

- Cleanability: The chain and its components should be easily accessible for cleaning and sanitation procedures. Quick disassembly and reassembly can also be beneficial for efficient cleaning processes.

- Regulatory Compliance: Compliance with food safety and sanitation regulations is of utmost importance. Engineering chains used in the food industry should meet industry standards and regulations to ensure product safety.

It’s crucial for food processing and packaging companies to work closely with chain suppliers who understand the specific requirements of the industry and offer chains designed and manufactured to meet these standards. Regular maintenance and inspections are essential to detect any signs of wear, damage, or contamination that could compromise the chain’s suitability for food-related applications.

By adhering to these guidelines and best practices, engineering chains can safely and effectively be used in food processing and packaging industries, contributing to the efficient and reliable operation of conveyor systems and other equipment in these critical sectors.

What are the different types of engineering chains available in the market?

Engineering chains come in various types, each designed to meet specific industrial needs and operating conditions. Here are some of the common types of engineering chains available in the market:

- Roller Chains: Roller chains are the most common type of engineering chain and consist of cylindrical rollers that engage with the sprocket teeth for smooth power transmission. They are widely used in industries like manufacturing, agriculture, and automotive.

- Drag Chains: Drag chains, also known as conveyor chains or slat chains, have flat, interlocking plates connected together. They are used in conveyor systems for material handling applications, especially in heavy-duty and abrasive environments.

- Hollow Pin Chains: Hollow pin chains feature hollow pins that allow for the insertion of cross rods or attachments, making them versatile for handling irregularly shaped loads or for use as a conveyor in specific industries.

- Double Pitch Chains: Double pitch chains have larger pitch distances between the links, resulting in lighter weight and lower cost. They are commonly used in low-speed and light-load applications.

- Leaf Chains: Leaf chains, also known as forklift chains, are used in lifting applications, such as forklift trucks and other material handling equipment.

- Side Bow Chains: Side bow chains have links with a curved or bent shape, allowing them to flex and bend laterally, making them suitable for curved or circular conveyor applications.

- Apron Chains: Apron chains are used in apron conveyors, typically found in the mining and cement industries, for transporting heavy and abrasive materials.

- Specialty Chains: There are various specialty chains available for specific industries and applications, such as escalator chains, agricultural chains, bottle conveyor chains, and more.

Each type of engineering chain has its own unique design and features to cater to specific requirements. The choice of chain type depends on factors like load capacity, speed, environmental conditions, and the application’s needs. It’s essential to select the appropriate chain type and ensure proper maintenance to achieve optimal performance and longevity in industrial operations.

editor by CX 2024-04-22

China Good quality Industrial Transmission Sugar Mill Straight Conveyor Roller Chain Alloy/Carbon Steel Engineering Chain

Product Description

CHINAMFG rollers enhance rotation on the bushing while reducing impact loads on the sprocket tooth during operation.

All components are heat treated to achieve maximum strength.

Pre-loaded during the manufacturing process to minimize initial elongation.

Hot dipped lubrication ensures 100% lubrication of all chain components to extend wear life and reduce maintenance costs.

| CHAIN NO. |

PITCH | BUSH WIDTH |

ROLLER DIA |

PIN | PLATE | MIN. TENSILE STRENGTH |

MAX. TENSILE STRENGTH |

WEIGHT | |||||||

| d | L1 | L2 | H | t/T | |||||||||||

| mm | mm | mm | mm | mm | mm | mm | mm | KN/min | KN/min | kg/m | |||||

| US101.6 | 101.60 | 31.80 | 57.15 | 15.88 | 34.40 | 38.40 | 38.10 | 6.40 | 72.3 | 8.20 | 11.67 | ||||

| P101.6-R47 | 101.60 | 30.00 | 47.00 | 15.88 | 41.00 | 45.00 | 41.00 | 10.00 | 242.0 | 19.40 | 17.98 | ||||

| US127 | 127.00 | 38.40 | 69.85 | 19.00 | 45.10 | 51.40 | 50.80 | 9.60 | 180.0 | 20.30 | 19.22 | ||||

| P152.4-R66.7 | 152.40 | 30.00 | 66.70 | 26.92 | 35.50 | 41.50 | 50.80 | 8.00 | 167.0 | 13.40 | 16.11 | ||||

| C9060 | 152.40 | 37.70 | 69.85 | 18.90 | 45.00 | 49.30 | 50.80 | 9.50 | 250.0 | 28.20 | 17.20 | ||||

| C 0571 1 | 152.40 | 37.70 | 69.85 | 18.90 | 44.90 | 50.30 | 57.20 | 9.50 | 377.9 | 28.20 | 18.74 | ||||

| C 0571 3 | 152.40 | 38.00 | 76.20 | 23.83 | 47.10 | 54.90 | 61.90 | 10.30 | 635.0 | 36.10 | 22.27 | ||||

| 1796 | 152.40 | 37.80 | 69.85 | 76.20 | 73.00 | 22.23 | 43.90 | 53.20 | 57.20 | 9.50 | 444.5 | 33.30 | 18.50 | 19.50 | 19.20 |

| Usage: | Transmission Chain, Conveyor Chain, Dedicated Special Chain, Roller Chain |

|---|---|

| Material: | Alloy/Carbon Steel |

| Surface Treatment: | Polishing |

| Feature: | Heat Resistant |

| Chain Size: | 4"*6" |

| Structure: | Roller Chain |

| Samples: |

US$ 10/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can engineering chains be used in overhead or inverted applications?

Yes, engineering chains can be used in both overhead and inverted applications, provided they are properly selected and installed. These types of applications are common in various industries, including material handling, automotive, and food processing. Engineering chains are versatile and well-suited for such applications due to their robust construction, flexibility, and ability to handle heavy loads.

Overhead applications involve suspending the chain from overhead beams or structures, while inverted applications require the chain to run on the underside of the conveyor or equipment. Some factors to consider when using engineering chains in these applications include:

- Corrosion Resistance: For overhead applications in outdoor environments or areas with exposure to moisture, it is essential to use engineering chains made from corrosion-resistant materials, such as stainless steel, to prevent rust and ensure longevity.

- Lubrication: Proper and regular lubrication is crucial for chains in both overhead and inverted applications to reduce friction, wear, and noise levels. Lubrication also helps protect the chain from contaminants and moisture.

- Load Capacity: Ensure that the engineering chain selected has a sufficient load capacity to handle the weight of the conveyed materials or equipment in the application.

- Installation: Proper installation is critical for the smooth operation of the chain in overhead and inverted applications. Correct tensioning and alignment will help prevent premature wear and improve overall performance.

- Chain Speed: Consider the speed at which the chain will be running in the application, as higher speeds may require additional considerations in terms of lubrication and wear.

By taking these factors into account and following the manufacturer’s guidelines for installation, lubrication, and maintenance, engineering chains can be used effectively in overhead and inverted applications. They offer reliable and efficient power transmission and material handling solutions, making them valuable components in a wide range of industrial processes and systems.

Can engineering chains be used in vertical lifting applications?

Yes, engineering chains can be used in vertical lifting applications, and they are commonly employed in various industries for this purpose. Vertical lifting applications require a reliable and robust power transmission solution, and engineering chains are well-suited to meet these demands.

1. High Load Capacity: Engineering chains are designed to handle heavy loads, making them suitable for vertical lifting applications where substantial weights need to be lifted and moved.

2. Safety Features: Many engineering chains used in lifting applications are designed with safety features, such as chain guides or guards, to prevent the chain from derailing or jumping off the sprockets during operation.

3. Controlled Motion: Engineering chains offer precise control over the lifting motion, which is crucial for vertical lifting tasks that require accuracy and stability.

4. Reliability: In vertical lifting applications, the chain must operate consistently and reliably to ensure the safety of workers and equipment. Engineering chains are known for their durability and long service life, making them a dependable choice for such critical tasks.

5. Customization: Engineering chains can be customized to fit specific vertical lifting applications. Different chain types, sizes, and attachments can be chosen to optimize performance and efficiency for a particular lifting task.

6. Lubrication: Proper lubrication is essential for engineering chains used in vertical lifting applications to minimize friction and wear, ensuring smooth and efficient operation.

7. Compliance: Depending on the industry and application, engineering chains may need to comply with specific safety standards and regulations, such as ISO or ANSI standards.

Overall, engineering chains are a reliable and versatile option for vertical lifting applications, providing the necessary strength, control, and safety required for lifting heavy loads with precision and efficiency.

Can engineering chains be used in corrosive or harsh environments?

Yes, engineering chains can be designed and manufactured to withstand corrosive or harsh environments. When operating in such conditions, it is crucial to select the appropriate materials and coatings for the chain to ensure its durability and performance. Here are some considerations for using engineering chains in corrosive or harsh environments:

1. Material Selection: Choose materials that have high corrosion resistance, such as stainless steel or nickel-plated chains. These materials can withstand exposure to moisture, chemicals, and other corrosive agents.

2. Coatings and Surface Treatments: Applying specialized coatings or surface treatments to the chain can further enhance its corrosion resistance. Common coatings include zinc plating, chromate conversion coating, and polymer coatings.

3. Sealed Joints: Opt for engineering chains with sealed joints or special seals to protect the internal components from contaminants and moisture, reducing the risk of corrosion.

4. Environmental Ratings: Some engineering chains may come with specific environmental ratings that indicate their suitability for certain conditions. Check these ratings to ensure the chain is appropriate for the intended environment.

5. Regular Maintenance: Even with corrosion-resistant materials and coatings, regular maintenance is essential. Keep the chain clean, lubricated, and free from debris to prevent corrosion and premature wear.

6. Compatibility with Other Components: Ensure that all components in the chain system, such as sprockets and bearings, are also suitable for use in corrosive environments.

7. Temperature Considerations: Take into account the operating temperature range of the environment. Some materials may perform differently at extreme temperatures, affecting the chain’s overall performance.

8. Chemical Exposure: If the chain will be exposed to specific chemicals or substances, verify that the chosen materials and coatings are resistant to those chemicals.

By carefully selecting the right materials, coatings, and design features, engineering chains can effectively handle corrosive or harsh environments, maintaining their functionality and longevity in challenging industrial applications.

editor by CX 2023-10-19

China Good quality Engineering and Construction Machinery Heavy Chain 180-2 a Series Stainless Steel Short Pitch Precision Duplex Roller Chains and Bush Chains for Steel Mill

Product Description

A Series Short Pitch Precision Duplex Roller Chains & Bush Chains

| ISO/ANSI/ DIN Chain No. |

Chain No. | Pitch

P |

Roller diameter

d1max |

Width between inner plates b1min mm |

Pin diameter

d2max |

Pin length | Inner plate depth h2max mm |

Plate thickness

Tmax |

Transverse Pt mm |

Tensile strength

Qmin |

Average tensile strength Q0 kN |

Weight per meter q kg/m |

|

| Lmax mm |

Lcmax mm |

||||||||||||

| 180-2 | 36A-2 | 57.150 | 35.71 | 35.48 | 17.46 | 138.6 | 144.4 | 53.60 | 7.20 | 65.84 | 560.50/127386 | 722.2 | 29.22 |

ROLLER CHAIN

Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic, industrial and agricultural machinery, including conveyors, wire- and tube-drawing machines, printing presses, cars, motorcycles, and bicycles. It consists of a series of short cylindrical rollers held together by side links. It is driven by a toothed wheel called a sprocket. It is a simple, reliable, and efficient means of power transmission.

CONSTRUCTION OF THE CHAIN

Two different sizes of roller chain, showing construction.

There are 2 types of links alternating in the bush roller chain. The first type is inner links, having 2 inner plates held together by 2 sleeves or bushings CHINAMFG which rotate 2 rollers. Inner links alternate with the second type, the outer links, consisting of 2 outer plates held together by pins passing through the bushings of the inner links. The “bushingless” roller chain is similar in operation though not in construction; instead of separate bushings or sleeves holding the inner plates together, the plate has a tube stamped into it protruding from the hole which serves the same purpose. This has the advantage of removing 1 step in assembly of the chain.

The roller chain design reduces friction compared to simpler designs, resulting in higher efficiency and less wear. The original power transmission chain varieties lacked rollers and bushings, with both the inner and outer plates held by pins which directly contacted the sprocket teeth; however this configuration exhibited extremely rapid wear of both the sprocket teeth, and the plates where they pivoted on the pins. This problem was partially solved by the development of bushed chains, with the pins holding the outer plates passing through bushings or sleeves connecting the inner plates. This distributed the wear over a greater area; however the teeth of the sprockets still wore more rapidly than is desirable, from the sliding friction against the bushings. The addition of rollers surrounding the bushing sleeves of the chain and provided rolling contact with the teeth of the sprockets resulting in excellent resistance to wear of both sprockets and chain as well. There is even very low friction, as long as the chain is sufficiently lubricated. Continuous, clean, lubrication of roller chains is of primary importance for efficient operation as well as correct tensioning.

LUBRICATION

Many driving chains (for example, in factory equipment, or driving a camshaft inside an internal combustion engine) operate in clean environments, and thus the wearing surfaces (that is, the pins and bushings) are safe from precipitation and airborne grit, many even in a sealed environment such as an oil bath. Some roller chains are designed to have o-rings built into the space between the outside link plate and the inside roller link plates. Chain manufacturers began to include this feature in 1971 after the application was invented by Joseph Montano while working for Whitney Chain of Hartford, Connecticut. O-rings were included as a way to improve lubrication to the links of power transmission chains, a service that is vitally important to extending their working life. These rubber fixtures form a barrier that holds factory applied lubricating grease inside the pin and bushing wear areas. Further, the rubber o-rings prevent dirt and other contaminants from entering inside the chain linkages, where such particles would otherwise cause significant wear.[citation needed]

There are also many chains that have to operate in dirty conditions, and for size or operational reasons cannot be sealed. Examples include chains on farm equipment, bicycles, and chain saws. These chains will necessarily have relatively high rates of wear, particularly when the operators are prepared to accept more friction, less efficiency, more noise and more frequent replacement as they neglect lubrication and adjustment.

Many oil-based lubricants attract dirt and other particles, eventually forming an CHINAMFG paste that will compound wear on chains. This problem can be circumvented by use of a “dry” PTFE spray, which forms a solid film after application and repels both particles and moisture.

VARIANTS DESIGN

Layout of a roller chain: 1. Outer plate, 2. Inner plate, 3. Pin, 4. Bushing, 5. Roller

If the chain is not being used for a high wear application (for instance if it is just transmitting motion from a hand-operated lever to a control shaft on a machine, or a sliding door on an oven), then 1 of the simpler types of chain may still be used. Conversely, where extra strength but the smooth drive of a smaller pitch is required, the chain may be “siamesed”; instead of just 2 rows of plates on the outer sides of the chain, there may be 3 (“duplex”), 4 (“triplex”), or more rows of plates running parallel, with bushings and rollers between each adjacent pair, and the same number of rows of teeth running in parallel on the sprockets to match. Timing chains on automotive engines, for example, typically have multiple rows of plates called strands.

Roller chain is made in several sizes, the most common American National Standards Institute (ANSI) standards being 40, 50, 60, and 80. The first digit(s) indicate the pitch of the chain in eighths of an inch, with the last digit being 0 for standard chain, 1 for lightweight chain, and 5 for bushed chain with no rollers. Thus, a chain with half-inch pitch would be a #40 while a #160 sprocket would have teeth spaced 2 inches apart, etc. Metric pitches are expressed in sixteenths of an inch; thus a metric #8 chain (08B-1) would be equivalent to an ANSI #40. Most roller chain is made from plain carbon or alloy steel, but stainless steel is used in food processing machinery or other places where lubrication is a problem, and nylon or brass are occasionally seen for the same reason.

Roller chain is ordinarily hooked up using a master link (also known as a connecting link), which typically has 1 pin held by a horseshoe clip rather than friction fit, allowing it to be inserted or removed with simple tools. Chain with a removable link or pin is also known as cottered chain, which allows the length of the chain to be adjusted. Half links (also known as offsets) are available and are used to increase the length of the chain by a single roller. Riveted roller chain has the master link (also known as a connecting link) “riveted” or mashed on the ends. These pins are made to be durable and are not removable.

USE

An example of 2 ‘ghost’ sprockets tensioning a triplex roller chain system

Roller chains are used in low- to mid-speed drives at around 600 to 800 feet per minute; however, at higher speeds, around 2,000 to 3,000 feet per minute, V-belts are normally used due to wear and noise issues.

A bicycle chain is a form of roller chain. Bicycle chains may have a master link, or may require a chain tool for removal and installation. A similar but larger and thus stronger chain is used on most motorcycles although it is sometimes replaced by either a toothed belt or a shaft drive, which offer lower noise level and fewer maintenance requirements.

The great majority of automobile engines use roller chains to drive the camshaft(s). Very high performance engines often use gear drive, and starting in the early 1960s toothed belts were used by some manufacturers.

Chains are also used in forklifts using hydraulic rams as a pulley to raise and lower the carriage; however, these chains are not considered roller chains, but are classified as lift or leaf chains.

Chainsaw cutting chains superficially resemble roller chains but are more closely related to leaf chains. They are driven by projecting drive links which also serve to locate the chain CHINAMFG the bar.

Sea Harrier FA.2 ZA195 front (cold) vector thrust nozzle – the nozzle is rotated by a chain drive from an air motor

A perhaps unusual use of a pair of motorcycle chains is in the Harrier Jump Jet, where a chain drive from an air motor is used to rotate the movable engine nozzles, allowing them to be pointed downwards for hovering flight, or to the rear for normal CHINAMFG flight, a system known as Thrust vectoring.

WEAR

The effect of wear on a roller chain is to increase the pitch (spacing of the links), causing the chain to grow longer. Note that this is due to wear at the pivoting pins and bushes, not from actual stretching of the metal (as does happen to some flexible steel components such as the hand-brake cable of a motor vehicle).

With modern chains it is unusual for a chain (other than that of a bicycle) to wear until it breaks, since a worn chain leads to the rapid onset of wear on the teeth of the sprockets, with ultimate failure being the loss of all the teeth on the sprocket. The sprockets (in particular the smaller of the two) suffer a grinding motion that puts a characteristic hook shape into the driven face of the teeth. (This effect is made worse by a chain improperly tensioned, but is unavoidable no matter what care is taken). The worn teeth (and chain) no longer provides smooth transmission of power and this may become evident from the noise, the vibration or (in car engines using a timing chain) the variation in ignition timing seen with a timing light. Both sprockets and chain should be replaced in these cases, since a new chain on worn sprockets will not last long. However, in less severe cases it may be possible to save the larger of the 2 sprockets, since it is always the smaller 1 that suffers the most wear. Only in very light-weight applications such as a bicycle, or in extreme cases of improper tension, will the chain normally jump off the sprockets.

The lengthening due to wear of a chain is calculated by the following formula:

M = the length of a number of links measured

S = the number of links measured

P = Pitch

In industry, it is usual to monitor the movement of the chain tensioner (whether manual or automatic) or the exact length of a drive chain (one rule of thumb is to replace a roller chain which has elongated 3% on an adjustable drive or 1.5% on a fixed-center drive). A simpler method, particularly suitable for the cycle or motorcycle user, is to attempt to pull the chain away from the larger of the 2 sprockets, whilst ensuring the chain is taut. Any significant movement (e.g. making it possible to see through a gap) probably indicates a chain worn up to and beyond the limit. Sprocket damage will result if the problem is ignored. Sprocket wear cancels this effect, and may mask chain wear.

CHAIN STRENGTH

The most common measure of roller chain’s strength is tensile strength. Tensile strength represents how much load a chain can withstand under a one-time load before breaking. Just as important as tensile strength is a chain’s fatigue strength. The critical factors in a chain’s fatigue strength is the quality of steel used to manufacture the chain, the heat treatment of the chain components, the quality of the pitch hole fabrication of the linkplates, and the type of shot plus the intensity of shot peen coverage on the linkplates. Other factors can include the thickness of the linkplates and the design (contour) of the linkplates. The rule of thumb for roller chain operating on a continuous drive is for the chain load to not exceed a mere 1/6 or 1/9 of the chain’s tensile strength, depending on the type of master links used (press-fit vs. slip-fit)[citation needed]. Roller chains operating on a continuous drive beyond these thresholds can and typically do fail prematurely via linkplate fatigue failure.

The standard minimum ultimate strength of the ANSI 29.1 steel chain is 12,500 x (pitch, in inches)2. X-ring and O-Ring chains greatly decrease wear by means of internal lubricants, increasing chain life. The internal lubrication is inserted by means of a vacuum when riveting the chain together.

CHAIN STHangZhouRDS

Standards organizations (such as ANSI and ISO) maintain standards for design, dimensions, and interchangeability of transmission chains. For example, the following Table shows data from ANSI standard B29.1-2011 (Precision Power Transmission Roller Chains, Attachments, and Sprockets) developed by the American Society of Mechanical Engineers (ASME). See the references[8][9][10] for additional information.

ASME/ANSI B29.1-2011 Roller Chain Standard SizesSizePitchMaximum Roller DiameterMinimum Ultimate Tensile StrengthMeasuring Load25

| ASME/ANSI B29.1-2011 Roller Chain Standard Sizes | ||||

| Size | Pitch | Maximum Roller Diameter | Minimum Ultimate Tensile Strength | Measuring Load |

|---|---|---|---|---|

| 25 | 0.250 in (6.35 mm) | 0.130 in (3.30 mm) | 780 lb (350 kg) | 18 lb (8.2 kg) |

| 35 | 0.375 in (9.53 mm) | 0.200 in (5.08 mm) | 1,760 lb (800 kg) | 18 lb (8.2 kg) |

| 41 | 0.500 in (12.70 mm) | 0.306 in (7.77 mm) | 1,500 lb (680 kg) | 18 lb (8.2 kg) |

| 40 | 0.500 in (12.70 mm) | 0.312 in (7.92 mm) | 3,125 lb (1,417 kg) | 31 lb (14 kg) |

| 50 | 0.625 in (15.88 mm) | 0.400 in (10.16 mm) | 4,880 lb (2,210 kg) | 49 lb (22 kg) |

| 60 | 0.750 in (19.05 mm) | 0.469 in (11.91 mm) | 7,030 lb (3,190 kg) | 70 lb (32 kg) |

| 80 | 1.000 in (25.40 mm) | 0.625 in (15.88 mm) | 12,500 lb (5,700 kg) | 125 lb (57 kg) |

| 100 | 1.250 in (31.75 mm) | 0.750 in (19.05 mm) | 19,531 lb (8,859 kg) | 195 lb (88 kg) |

| 120 | 1.500 in (38.10 mm) | 0.875 in (22.23 mm) | 28,125 lb (12,757 kg) | 281 lb (127 kg) |

| 140 | 1.750 in (44.45 mm) | 1.000 in (25.40 mm) | 38,280 lb (17,360 kg) | 383 lb (174 kg) |

| 160 | 2.000 in (50.80 mm) | 1.125 in (28.58 mm) | 50,000 lb (23,000 kg) | 500 lb (230 kg) |

| 180 | 2.250 in (57.15 mm) | 1.460 in (37.08 mm) | 63,280 lb (28,700 kg) | 633 lb (287 kg) |

| 200 | 2.500 in (63.50 mm) | 1.562 in (39.67 mm) | 78,175 lb (35,460 kg) | 781 lb (354 kg) |

| 240 | 3.000 in (76.20 mm) | 1.875 in (47.63 mm) | 112,500 lb (51,000 kg) | 1,000 lb (450 kg |

For mnemonic purposes, below is another presentation of key dimensions from the same standard, expressed in fractions of an inch (which was part of the thinking behind the choice of preferred numbers in the ANSI standard):

| Pitch (inches) | Pitch expressed in eighths |

ANSI standard chain number |

Width (inches) |

|---|---|---|---|

| 1⁄4 | 2⁄8 | 25 | 1⁄8 |

| 3⁄8 | 3⁄8 | 35 | 3⁄16 |

| 1⁄2 | 4⁄8 | 41 | 1⁄4 |

| 1⁄2 | 4⁄8 | 40 | 5⁄16 |

| 5⁄8 | 5⁄8 | 50 | 3⁄8 |

| 3⁄4 | 6⁄8 | 60 | 1⁄2 |

| 1 | 8⁄8 | 80 | 5⁄8 |

Notes:

1. The pitch is the distance between roller centers. The width is the distance between the link plates (i.e. slightly more than the roller width to allow for clearance).

2. The right-hand digit of the standard denotes 0 = normal chain, 1 = lightweight chain, 5 = rollerless bushing chain.

3. The left-hand digit denotes the number of eighths of an inch that make up the pitch.

4. An “H” following the standard number denotes heavyweight chain. A hyphenated number following the standard number denotes double-strand (2), triple-strand (3), and so on. Thus 60H-3 denotes number 60 heavyweight triple-strand chain.

A typical bicycle chain (for derailleur gears) uses narrow 1⁄2-inch-pitch chain. The width of the chain is variable, and does not affect the load capacity. The more sprockets at the rear wheel (historically 3-6, nowadays 7-12 sprockets), the narrower the chain. Chains are sold according to the number of speeds they are designed to work with, for example, “10 speed chain”. Hub gear or single speed bicycles use 1/2″ x 1/8″ chains, where 1/8″ refers to the maximum thickness of a sprocket that can be used with the chain.

Typically chains with parallel shaped links have an even number of links, with each narrow link followed by a broad one. Chains built up with a uniform type of link, narrow at 1 and broad at the other end, can be made with an odd number of links, which can be an advantage to adapt to a special chainwheel-distance; on the other side such a chain tends to be not so strong.

Roller chains made using ISO standard are sometimes called as isochains.

WHY CHOOSE US

1. Reliable Quality Assurance System

2. Cutting-Edge Computer-Controlled CNC Machines

3. Bespoke Solutions from Highly Experienced Specialists

4. Customization and OEM Available for Specific Application

5. Extensive Inventory of Spare Parts and Accessories

6. Well-Developed CHINAMFG Marketing Network

7. Efficient After-Sale Service System

The 219 sets of advanced automatic production equipment provide guarantees for high product quality. The 167 engineers and technicians with senior professional titles can design and develop products to meet the exact demands of customers, and OEM customizations are also available with us. Our sound global service network can provide customers with timely after-sales technical services.

We are not just a manufacturer and supplier, but also an industry consultant. We work pro-actively with you to offer expert advice and product recommendations in order to end up with a most cost effective product available for your specific application. The clients we serve CHINAMFG range from end users to distributors and OEMs. Our OEM replacements can be substituted wherever necessary and suitable for both repair and new assemblies.

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Motorcycle, Food Machinery, Mining Equipment, Agricultural Machinery, Car, Textile Machinery, Garment Machinery, Conveyor |

| Surface Treatment: | Polishing |

| Structure: | Roller Chain |

| Material: | Alloy |

| Type: | Derrck, Bush Chain |

| Samples: |

US$ 0/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can engineering chains be used for power transmission in mining equipment?

Yes, engineering chains are commonly used for power transmission in various mining equipment applications. Mining operations involve heavy-duty machinery that requires robust and reliable power transmission systems to handle the demanding conditions and loads. Engineering chains are well-suited for these challenging environments due to their strength, durability, and versatility.

In mining equipment, engineering chains are used in various applications, including:

- Conveyors: Mining conveyors transport raw materials and ores over long distances, and engineering chains play a crucial role in driving these conveyors and ensuring smooth material flow.

- Bucket Elevators: Bucket elevators are used to vertically lift and transfer materials, and engineering chains provide the power transmission required for their operation.

- Crushers and Pulverizers: Engineering chains are used to drive crushers and pulverizers, which reduce the size of mined materials for further processing.

- Draglines and Excavators: These large mining machines use engineering chains to power their movement and operation.

- Stackers and Reclaimers: These machines stack and reclaim bulk materials in storage yards, and engineering chains facilitate their movement and positioning.

Engineering chains are preferred in mining applications because they can withstand heavy loads, shock loads, and harsh environmental conditions commonly found in mining operations. Additionally, engineering chains are available in various sizes, pitches, and configurations, making them adaptable to different mining equipment designs and requirements.

To ensure reliable performance, it is essential to select the appropriate type and size of engineering chain for each specific mining equipment application. Regular maintenance and proper lubrication are also critical to extend the chain’s service life and minimize downtime in mining operations.

What are the benefits of using an engineering chain in material handling systems?

An engineering chain offers several advantages when used in material handling systems, making it a popular choice for various industrial applications:

1. High Strength and Durability: Engineering chains are designed to withstand heavy loads and offer high tensile strength, making them ideal for material handling tasks that involve transporting heavy or bulky items.

2. Reliable Power Transmission: Engineering chains provide a reliable means of power transmission, ensuring smooth and efficient movement of materials within the handling system.

3. Versatility: These chains are available in various configurations and sizes, allowing for customization to fit different material handling equipment and conveyor systems.

4. Flexibility: Engineering chains can be used in both straight-line and curved conveyor systems, offering flexibility in designing material flow paths.

5. Low Maintenance: When properly lubricated and maintained, engineering chains have a long service life with minimal maintenance requirements, reducing downtime and overall operating costs.

6. Corrosion Resistance: For material handling systems operating in harsh environments, corrosion-resistant engineering chains, such as stainless steel chains, can be used to prevent degradation and ensure longevity.

7. Wide Range of Applications: Engineering chains are suitable for a wide range of material handling applications, including manufacturing, warehousing, distribution centers, and more.

8. Precise Control: These chains offer precise control over the movement of materials, enabling accurate positioning and synchronization in automated material handling systems.

9. Reduced Noise and Vibration: Engineering chains are designed to operate quietly and with minimal vibration, contributing to a more comfortable and quieter working environment.

10. Safety: The reliability and strength of engineering chains enhance the safety of material handling operations, reducing the risk of chain failure and related accidents.

Overall, the use of engineering chains in material handling systems ensures efficient and dependable movement of goods and materials, contributing to increased productivity, reduced downtime, and improved safety in industrial environments.

What is an engineering chain and what are its uses in various industries?

An engineering chain, also known as an industrial chain, is a type of power transmission chain widely used in various industries for transmitting mechanical power between two or more rotating shafts. It consists of a series of interconnected links that form a flexible and durable mechanism capable of handling heavy loads and harsh operating conditions. Here are its uses in different industries:

1. Manufacturing Industry:

In the manufacturing sector, engineering chains are employed in conveyor systems for material handling, assembly lines, and automated production processes. They facilitate the movement of raw materials, workpieces, and finished products efficiently, streamlining production and reducing manual labor.

2. Automotive Industry:

Automotive manufacturing relies heavily on engineering chains for conveying car parts during assembly. From the production of engines to body assembly, these chains ensure a smooth and continuous flow of components through the manufacturing process.

3. Agriculture and Farming:

In the agricultural sector, engineering chains are used in machinery such as tractors and combine harvesters. They facilitate power transmission from the engine to different agricultural implements, enabling various tasks like plowing, seeding, and harvesting.

4. Construction and Mining:

Construction equipment and mining machinery utilize engineering chains for heavy-duty power transmission. These chains are suitable for harsh environments and high-load applications, making them ideal for conveying construction materials and excavating operations.

5. Oil and Gas Industry:

In the oil and gas sector, engineering chains are utilized in drilling rigs and oil extraction equipment. They assist in the rotation of drill bits and the transfer of power within complex drilling systems.

6. Food and Beverage Industry:

Engineering chains find applications in food processing and beverage manufacturing, where they are used in conveyor systems for handling ingredients, packaging, and bottling processes. Specialized food-grade chains are designed to meet strict hygiene standards.

7. Material Handling:

Across various industries, engineering chains are widely employed in material handling systems, including overhead cranes, hoists, and elevators. They ensure smooth and efficient movement of heavy loads in warehouses, distribution centers, and manufacturing facilities.

8. Pulp and Paper Industry:

In the pulp and paper industry, engineering chains are used in paper processing machines, pulp digesters, and paper converting equipment. They contribute to the continuous flow of paper products during manufacturing.

9. Renewable Energy:

In the renewable energy sector, engineering chains are utilized in wind turbines and solar tracking systems. They assist in adjusting the position of solar panels and wind turbine blades to optimize energy capture.

10. Power Generation:

In power plants, engineering chains are used in various equipment, including conveyor systems for transporting fuel and ash, as well as in boiler feed systems and other power generation processes.

11. Water and Wastewater Treatment:

Engineering chains are employed in water treatment plants for sludge dewatering and in wastewater treatment plants for handling sludge and screenings.

12. Textile Industry:

In textile machinery, engineering chains assist in the production process, including spinning, weaving, and fabric handling.

13. Printing Industry:

In printing presses, engineering chains facilitate the smooth movement of paper during the printing process.

14. Packaging Industry:

Engineering chains are utilized in packaging machinery for handling boxes, cartons, and other packaging materials.

Overall, engineering chains are versatile components that play a crucial role in various industries for power transmission and material handling applications. They provide reliability, durability, and efficiency, making them an essential part of modern industrial processes.

editor by CX 2023-09-25

China Best Sales Good Service High Precision Machinery Engineering Industrial Competitive Price Agricultural Chain with Attachment

Product Description

Good Service High Precision Machinery Engineering Industrial Competitive Price Agricultural Chain with Attachment

Product Description

1. Material: Alloy steel & Stainless steel

2. Surface treatment: Shot peening / Zinc-plated / Nickel-plated / Dacromet-plated

3. Characteristic: Chain plate hole finally passed ball extrusion to ensure maximum fatigue resistance, parts of shot peening treatment makes the chain and the sleeve has a higher fatigue strength.

| Materials Available | 1. Stainless Steel: SS304, SS316, etc |

| 2. Alloy Steel: 45Mn, 42CrMo, etc | |

| 3. OEM according to your request | |

| Surface Treatment | Shot peening, Polishing, Oxygenation, Blackening, Zinc-plated, Nickel-plated, Anodized, etc. |

| Characteristic | Fire Resistant, Oil Resistant, Heat Resistant |

| Application | Agricultural machine |

| Design criterion | ISO DIN ANSI & Customer’s Drawing |

| Size | Customer’s Drawing & ISO standard |

| Package | Wooden Case / Container and pallet, or made-to-order |

| Certificate | ISO9001: 2008 |

| Advantage | First quality, best service, competitive price, fast delivery |

| Delivery Time | 20 days for samples. 45 days for official order. |

Detailed Photos

View more products,please click here…

Company Profile

| Material: | Alloy/Carbon Steel |

|---|---|

| Sample: | for Free |

| Transport Package: | Plastic Bag+Carton Box+Plywood Case |

| Specification: | S55K1, S62A2K1 |

| Trademark: | made-to-order |

| Origin: | China |

| Samples: |

US$ 0/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the limitations of using engineering chains in certain applications?

While engineering chains are versatile and widely used in various industries, they do have some limitations that should be considered when selecting them for specific applications:

- Speed Limitations: Engineering chains have a maximum recommended speed limit. High-speed applications may require specialized high-speed chains that are designed to reduce vibration and noise and maintain reliable performance at elevated speeds.

- Temperature Sensitivity: Extreme temperatures can affect the performance of engineering chains. In high-temperature environments, chains may experience accelerated wear and reduced strength. Similarly, in cryogenic conditions, the chain’s materials may become brittle and prone to breakage.

- Chemical Exposure: Exposure to corrosive chemicals or harsh environments can lead to chain degradation. Engineering chains used in such conditions should be made from materials that offer corrosion resistance or be appropriately coated to withstand chemical exposure.

- Shock Loads: While engineering chains can handle moderate shock loads and impact forces, excessive or sudden shock loads can cause chain failure. In applications with significant shock loads, additional measures such as shock-absorbing devices may be required.

- Maintenance Requirements: Engineering chains require regular maintenance, including proper lubrication and periodic inspection for wear and damage. Failure to maintain the chains can result in premature wear and unexpected failures.

- Alignment: Engineering chains may not perform optimally in applications with misaligned sprockets. Proper alignment is essential to ensure smooth operation and prevent excessive wear.

- Environmental Contaminants: Dust, dirt, and debris in certain environments, such as construction sites or agricultural fields, can accumulate on the chain and sprockets, leading to accelerated wear and reduced chain life.

- Load Capacity: While engineering chains have excellent load-carrying capabilities, applications with extremely high loads may require customized or heavy-duty chains to meet the specific requirements.

Understanding the limitations of engineering chains allows engineers and designers to make informed decisions when selecting the most suitable chain type for their applications. By considering factors like speed, temperature, chemical exposure, shock loads, and maintenance requirements, one can ensure the reliable and efficient performance of engineering chains in various industrial settings.

How do engineering chains handle product accumulation and spacing in conveyor systems?

In conveyor systems, product accumulation and spacing are essential considerations to ensure smooth and efficient material handling. Engineering chains play a crucial role in managing product flow and maintaining proper spacing between items. Here’s how they handle these tasks:

1. Accumulation: Engineering chains can be designed with special attachments that allow for product accumulation. These attachments create zones on the conveyor where products can accumulate without interrupting the overall conveyor operation. The accumulation zones are usually equipped with sensors or photo eyes to detect product presence and control the chain’s movement, preventing collisions and jams.

2. Spacing: To achieve proper spacing between products on the conveyor, engineering chains may be equipped with specially designed attachments or guides. These guides ensure that each item is evenly spaced from the one in front of it, preventing product collisions and maintaining a consistent flow. The spacing between products can be adjusted by modifying the length of the conveyor or changing the attachment configuration on the chain.

3. Timing and Synchronization: In automated conveyor systems, engineering chains are often used to synchronize the movement of products. Through precise control and positioning, the chain ensures that items are released at the correct intervals, maintaining the desired spacing and preventing congestion.

4. Low Back Pressure: Engineering chains can be designed with low back pressure accumulation, which allows products to accumulate while maintaining gentle contact with each other. This reduces the risk of damage to delicate or sensitive items and improves overall product handling.

5. Diverter and Merge Solutions: Engineering chains can incorporate diverters and merge units to redirect products to different conveyor lines while maintaining proper spacing. These units efficiently manage product flow and distribution in complex conveyor systems.

6. Customization: Manufacturers can customize engineering chains to suit specific product sizes, weights, and handling requirements. This ensures optimal performance and reduces the risk of jams or disruptions in the conveyor system.

Overall, engineering chains are integral components in conveyor systems, enabling effective product accumulation and spacing. Their precise control, customizability, and synchronization capabilities contribute to the smooth and efficient operation of material handling processes in various industries.

Can engineering chains be used in high-speed applications?

Yes, engineering chains can be used in high-speed applications, but their suitability depends on various factors. While some engineering chains are designed to handle high-speed operation, others may not be suitable for such applications. Here are some considerations:

1. Chain Type: Different types of engineering chains have varying capabilities when it comes to high-speed operation. For example, roller chains are commonly used in industrial applications and can handle moderate to high speeds efficiently. On the other hand, conveyor chains or specialty chains may have limitations on speed due to their design and intended use.

2. Manufacturer Specifications: Check the manufacturer’s specifications and recommendations for the engineering chain you plan to use. Manufacturers often provide maximum allowable speeds for their chains based on factors such as chain size, material, and construction.

3. Lubrication and Maintenance: Proper lubrication and maintenance are critical for high-speed applications. Adequate lubrication reduces friction and wear, allowing the chain to operate smoothly at higher speeds. Regular maintenance ensures that the chain remains in good condition and minimizes the risk of unexpected failures.

4. Load and Tension: High-speed applications can place additional loads and tension on the engineering chain. It is essential to ensure that the chain can handle the increased loads and tension without stretching excessively or experiencing premature wear.

5. Environmental Conditions: Consider the environmental factors that may affect the chain’s performance at high speeds. Temperature, humidity, and the presence of contaminants can impact the chain’s wear and durability.

6. Safety Considerations: High-speed applications require careful consideration of safety measures. Ensure that all safety guidelines and regulations are followed to prevent accidents or injuries resulting from chain failure.

In summary, engineering chains can be used in high-speed applications, but it is essential to select the appropriate chain type and ensure proper maintenance and lubrication. Consulting with chain manufacturers or experts can help you determine the most suitable engineering chain for your specific high-speed application, ensuring safe and reliable operation.

editor by CX 2023-09-19

China Good quality Flexible Plastic Cable Chain Engineering Nylon Drag Chain

Product Description

Product Description

1.Material:reinforced nylon. It can stand with high pressure and has good tensile strength,toughness and elasticity ,wearing and falmable resisance.2.Resistances:It is oil and acceleration is 5m/sec.(specfic speed and acceleration depends on specific).3.Service life:Under normal conmal condition,5 million reciprocating motions can be reached(which is also related to the operating conditions.)

Technical data:

|

Tensile strength |

180N/mm2 | Volume resistance | 1571-1015 |

| Impact strength | 50Kj/m2 | Water Absorption | 4% |

| Tenprature range | -40.C-130.C | Friction factor | 0.3 |

| Surface resistaned | 1571-1012 | Falme resistance | HB(UL49) |

Details

Application

The Engineering Plastic Roller Chain Cable Drag Chain has been widely used in CNC machine tools, electronic equipment, stone machinery, glass machinery, doors and windows machines, injection molding machines, mechanical hands, overweight transportation equipment, automated warehouses.

Installation

1.Put a screw driver vertically into the opening hole at both ends of the cover and then open the cover .Put the drag chain for cables and oip pipes according to the instructions provided .Put the cover back.Note that the fixed end and the moving end of a cable should be fixed by using a tension device

2.When used in a long sliding service,it is recommended to use a guiding grove,Please ask our technical personnel about the usage of the guiding grove.

Order notice :

Kindly please advise the below:

1. Length:

2. Cable or pipe Max. Dia.:

3. Supporting board type:

4. Bending Radius(or the curved height ):

Company Profile

ZheJiang CZPT Conductor Busbar Electrical Co.,Ltd. Is located in ZheJiang ,Established in 2001 and have been involved in this field for more than 10 years.CZPT is professional enterprise in searching and developing the electrical products and engineering.The main products includes:conductor rail system .bus duct system,cable festoon system ,cable drag chain cable tray,lighting busbar and related accessories, our products used in mobile power supply for crane ,electrical hoist .as well as factory,high building power distribution.With excellent products quality ,good service our products are greatly favored bycustomers around the domestic and foreign market, we will devote ourselves to provide better service for the whole world customer.

Packaging & Shipping

Welcome to inquiry ~

| Surface Treatment: | Polishing |

|---|---|

| Material: | Plastic |

| Bending Radius: | 50mm-750mm |

| Max.Width(mm): | 200mm-650mm |

| Feature: | Fire Resistant, Oil Resistant, Heat Resistant |

| Pitch: | 45mm-180mm |

| Customization: |

Available

| Customized Request |

|---|

What are the limitations of using engineering chains in certain applications?

While engineering chains are versatile and widely used in various industries, they do have some limitations that should be considered when selecting them for specific applications:

- Speed Limitations: Engineering chains have a maximum recommended speed limit. High-speed applications may require specialized high-speed chains that are designed to reduce vibration and noise and maintain reliable performance at elevated speeds.

- Temperature Sensitivity: Extreme temperatures can affect the performance of engineering chains. In high-temperature environments, chains may experience accelerated wear and reduced strength. Similarly, in cryogenic conditions, the chain’s materials may become brittle and prone to breakage.

- Chemical Exposure: Exposure to corrosive chemicals or harsh environments can lead to chain degradation. Engineering chains used in such conditions should be made from materials that offer corrosion resistance or be appropriately coated to withstand chemical exposure.

- Shock Loads: While engineering chains can handle moderate shock loads and impact forces, excessive or sudden shock loads can cause chain failure. In applications with significant shock loads, additional measures such as shock-absorbing devices may be required.

- Maintenance Requirements: Engineering chains require regular maintenance, including proper lubrication and periodic inspection for wear and damage. Failure to maintain the chains can result in premature wear and unexpected failures.

- Alignment: Engineering chains may not perform optimally in applications with misaligned sprockets. Proper alignment is essential to ensure smooth operation and prevent excessive wear.

- Environmental Contaminants: Dust, dirt, and debris in certain environments, such as construction sites or agricultural fields, can accumulate on the chain and sprockets, leading to accelerated wear and reduced chain life.

- Load Capacity: While engineering chains have excellent load-carrying capabilities, applications with extremely high loads may require customized or heavy-duty chains to meet the specific requirements.

Understanding the limitations of engineering chains allows engineers and designers to make informed decisions when selecting the most suitable chain type for their applications. By considering factors like speed, temperature, chemical exposure, shock loads, and maintenance requirements, one can ensure the reliable and efficient performance of engineering chains in various industrial settings.

Can engineering chains be used in low-temperature or cryogenic environments?

Yes, engineering chains can be used in low-temperature or cryogenic environments with appropriate material selection and lubrication. When operating in extremely cold conditions, standard chain materials may become brittle and prone to failure. However, by using special materials and lubricants designed for low temperatures, engineering chains can maintain their performance and reliability.

In cryogenic applications, such as in the aerospace, medical, or scientific industries, where temperatures can reach extremely low levels (typically below -150°C or -238°F), standard steel chains may not be suitable. In such cases, engineers often opt for materials like stainless steel, nickel-plated steel, or other alloys that can withstand cryogenic temperatures without losing their mechanical properties.

Lubrication is another critical consideration in low-temperature environments. Conventional lubricants may freeze or become less effective at extremely cold temperatures, leading to increased friction and wear. Therefore, special lubricants that remain fluid at low temperatures, such as synthetic oils or greases designed for cryogenic use, should be applied to ensure smooth chain operation and reduce wear.

In summary, engineering chains can be used in low-temperature or cryogenic environments, provided that the appropriate materials and lubricants are chosen for the specific application. By selecting the right chain and ensuring proper lubrication, the performance and service life of the engineering chain can be maintained even in extreme cold conditions.

Can engineering chains be used in corrosive or harsh environments?

Yes, engineering chains can be designed and manufactured to withstand corrosive or harsh environments. When operating in such conditions, it is crucial to select the appropriate materials and coatings for the chain to ensure its durability and performance. Here are some considerations for using engineering chains in corrosive or harsh environments:

1. Material Selection: Choose materials that have high corrosion resistance, such as stainless steel or nickel-plated chains. These materials can withstand exposure to moisture, chemicals, and other corrosive agents.

2. Coatings and Surface Treatments: Applying specialized coatings or surface treatments to the chain can further enhance its corrosion resistance. Common coatings include zinc plating, chromate conversion coating, and polymer coatings.

3. Sealed Joints: Opt for engineering chains with sealed joints or special seals to protect the internal components from contaminants and moisture, reducing the risk of corrosion.

4. Environmental Ratings: Some engineering chains may come with specific environmental ratings that indicate their suitability for certain conditions. Check these ratings to ensure the chain is appropriate for the intended environment.

5. Regular Maintenance: Even with corrosion-resistant materials and coatings, regular maintenance is essential. Keep the chain clean, lubricated, and free from debris to prevent corrosion and premature wear.

6. Compatibility with Other Components: Ensure that all components in the chain system, such as sprockets and bearings, are also suitable for use in corrosive environments.

7. Temperature Considerations: Take into account the operating temperature range of the environment. Some materials may perform differently at extreme temperatures, affecting the chain’s overall performance.

8. Chemical Exposure: If the chain will be exposed to specific chemicals or substances, verify that the chosen materials and coatings are resistant to those chemicals.

By carefully selecting the right materials, coatings, and design features, engineering chains can effectively handle corrosive or harsh environments, maintaining their functionality and longevity in challenging industrial applications.

editor by CX 2023-09-08

China Good quality Standard Engineering New Colored Conveyor Belts POM Plastic Roller Chain

Product Description

Wholesale ISO standard engineering new colored conveyor belts pom plastic roller chain

Advantages:

1.A complete range of specification

2.free design offer OEM & ODM

3.free sample available

4.professional service team

5.specialize CNC machining and injection over 10 years

6.Custom accept as per drawing or sample

POM (Polyformaldehyde)

POM (Full-name: Polyformaldehyde), is a engineering plastics of non-side-chain, high density, high crystalline and linear polymer, which is praised “Plastic Steel”, and has comprehensive excellent performances, such as: wear-resistance, high hardness, anti-impregnant, good rigidity (Tensile modulus of elasticity), chemical stability, isolation resistance and dimensional stability. POM has widely applied in Automobile industries, electronic and electric products, commodity, pipeline & fittings, exact apparatus and so on, which can be instead of the bronze, Zinc, tin and other metals.

Except POM-H, is often copolymerized with ethylene oxide together, in order to avoid the melting of POM material in the high temperature. POM-H has the better performances than POM-C in its high crystalline, mechanical strength and rigidity. And POM-C has the better performances than POM-H in its low melting point, temperature stability, fluxion characteristic and machining capability.

Father more, POM-H+PTFE, which is made from the Delrin POM Resin that maxed Teflon fiber symmetrically, has the low co-efficient of frication, good lubrication, wear-resistance, non-creepage resistance.

Automobile industries: POM has a large application in car industries, because the mechanical parts made by POM, which has the advantages of high mechanical strength, high hardness, good wear-resistance, low co-efficient of friction, easy to maintain, reducing cost and so on, can be used in cars instead of coppery half stalk and planet gear. It not only saving copper materials, but also improving service life. At the engine fuel system, components for hose valves and case cover of radiator, cooling fluid’s standby case, water valve, oil box’ cover, pump impeller, shell of gasification machine and accelerator pedal and so on.

Electronic and electric Industries: because of its lower power consuming, high dielectric strength and insulation resistance and electronic arc resistance, POM has widely applied in electronic and electric Industries, such as: shell of electronic spanner, shell of electronic scissors, shell of coal drilling machine ,handle of switch, parts also for phone, wireless recorder, video tape recorder, television, computer, electrograph, calculagraph, bracket of recorder tape and so on.

Agricultural machine: part of manual sprayer, joint and transport part of seeder, parts of milk machine, shell of irrigation and drainage, valve, joint and bush of water and so on.

Other field:

Pharmacy & packing Machine: transporting screw, planet gear, gear bar, chain wheel and cushion bar and so on.

Construction industries: water tap, window frame, wash pot, water tank, pulley for portiere, shell of water meter and tie-in of water pipe.

Color:White,Black,Natural,Rice Yellow brown and so on.

Size:1000X2000X(Thickness:1-200mm),1220X2440X(Thickness:1-200mm)

600X1200X(Thickness:1-200mm)

| Model |

inejction POM conveyor chain |

| Material |

POM / Nylon/ PVC or customized |

| Diameter | 1-250mm or customized |

| Length | 500mm,1000mmor customized |

| Color | Natural,White,Black,ect. |

| OEM & ODM | Yes |

| Certification | ISO9001,SGS,FDA,RoHS,Test Report,ect. |

| Free Sample | Yes |

| Density | 1.6g/ cm2 |

| Shape | sheet, rod, tube, gear, pulley, guide rail……or according to your demand |

| Packing | Plastic bags,Cartons,Wodden case,Pallet,Container,ect. |

| Advantage | One stop procurement |

Product Photo

| Material: | Plastic |

|---|---|

| Structure: | Leaf Chain |

| Surface Treatment: | Polishing |

| Chain Size: | 1/2"*3/32" |

| Feature: | Fire Resistant, Heat Resistant |

| Certificate: | ISO9001: 2008, Test Report |

| Customization: |

Available

| Customized Request |

|---|

What are the signs of wear and when should an engineering chain be replaced?

Identifying signs of wear in an engineering chain is crucial for maintaining the system’s reliability and preventing unexpected failures. Here are some common signs of wear in an engineering chain that indicate it may need replacement:

1. Elongation: Over time, chains can elongate due to wear on the pins and bushings. Measure the chain’s pitch (center-to-center distance between pins) and compare it to the original pitch. If the elongation exceeds the manufacturer’s recommended limit, it’s time to replace the chain.

2. Chain Stretch: Chain stretch occurs when the chain has excessive play or slack when engaged with the sprockets. This can result from elongation and may lead to a loss of accuracy in the system’s operation.

3. Increased Noise: Excessive wear can cause the chain to produce more noise during operation. If you notice a significant increase in chain noise, it may indicate wear or inadequate lubrication.

4. Chain Damage: Inspect the chain for signs of damage, such as bent or broken links, cracked plates, or damaged rollers. Damaged components compromise the chain’s integrity and can lead to failure.

5. Rust and Corrosion: Chains used in corrosive environments may show signs of rust and corrosion. Corroded components can weaken the chain and reduce its load-carrying capacity.

6. Frequent Maintenance and Repairs: If you find yourself frequently performing maintenance and repairs on the chain, it may be an indication that it is nearing the end of its service life.

7. Chain Misalignment: Excessive wear can cause the chain to misalign with the sprockets, leading to uneven wear patterns on the chain components.

8. Loss of Tension: In applications where tension is crucial for proper chain engagement, a loss of tension could indicate wear or elongation.

9. Reduced Performance: If the system’s performance, such as speed or accuracy, is noticeably reduced, it could be due to chain wear affecting the overall functionality.